Perché i clienti ci scelgono :

- Produttore-Controllo diretto

- Supporto ingegneristico

- Qualità costante

- Tempi di consegna affidabili

Fiberglass rods are composite rod products manufactured from continuous glass fibers and thermoset resin using the pultrusion process.

They are commonly selected for applications that require corrosion resistance, electrical insulation, and dimensional stability without the weight and conductivity of metal rods.

In industrial and OEM contexts, fiberglass rods are specified based on diameter control, stiffness behavior, and supply form, rather than aesthetic appearance.

These criteria help determine whether a solid structural rod, a flexible rod, or fiberglass rod stock is most suitable for a given application.

The following fiberglass rod categories are defined by functional use and structural behavior for OEM and industrial applications.

Fiberglass tent rods are used in tent pole systems and outdoor shelters, providing controlled flexibility and weather resistance.

They are also supplied as replacement fiberglass tent rods for maintenance and aftermarket use.

Flexible fiberglass rods are designed to bend and recover under load, commonly used in pole systems, markers, and elastic support applications.

Solid fiberglass rods are pultruded composite rods selected for structural support where dimensional stability is required.

Fiberglass rods are supplied in multiple diameters and lengths for structural and flexible applications.

| Specification Item | Typical Options |

| Rod Type | Solid fiberglass rods / Flexible fiberglass rods |

| Diameter | Common inch sizes (including 3/8, 1/2, 3/4) and custom diameters |

| Length | Cut-to-length supply; long-length rods available on request |

| Resin System | Standard industrial resin; epoxy fiberglass rod option |

| Surface Finish | Smooth or sanded surface |

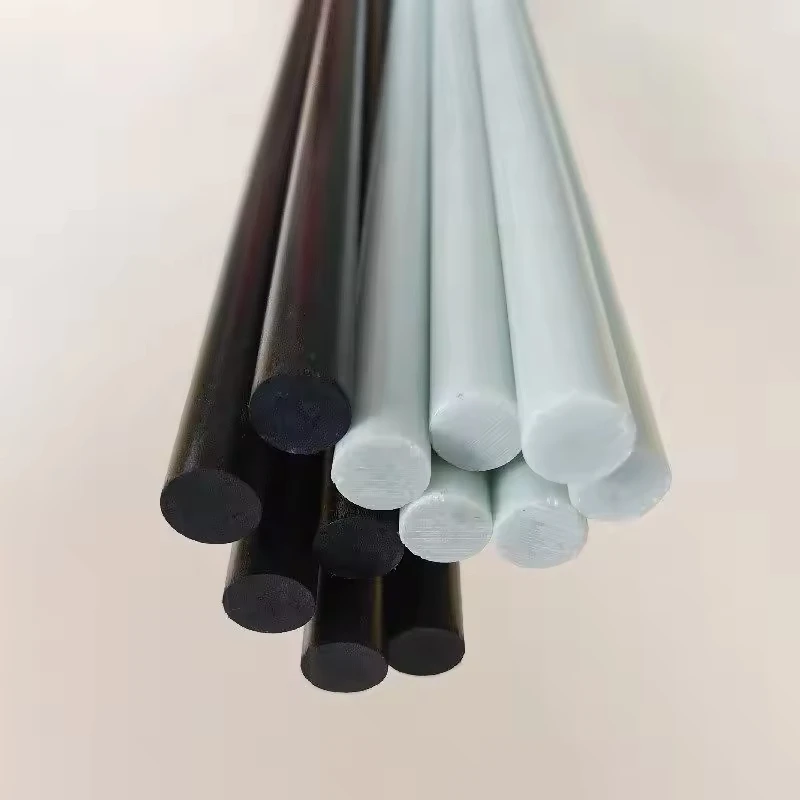

| Color | Natural fiberglass color or custom colors |

| Supply Form | Straight rods, sections, or rod stock for machining |

Fiberglass rods are applied across different industrial and outdoor scenarios, with selection driven by stiffness behavior and installation method.

Fiberglass tent rods are widely used in tent pole systems and outdoor shelters, providing reliable flexibility and weather resistance.

They are also supplied as replacement fiberglass tent rods for repair and aftermarket kits.

Flexible fiberglass rods are used in pole systems, markers, and guide rods where controlled bending and recovery are required.

Solid fiberglass rods are used for structural support, handles, spacers, and general industrial assemblies where dimensional stability is required.

Fiberglass rod stock is commonly supplied for cutting, machining, and assembly into OEM components and fixtures.

Fiberglass threaded rods and fiberglass sucker rods are used in corrosive or non-conductive environments, including industrial fastening and energy-related systems.

The following points highlight our manufacturing consistency, specification control, and supply reliability for fiberglass rod production.

Fiberglass rods are produced using a controlled pultrusion process to ensure consistent diameter, straightness, and fiber alignment across batches.

Rod type, stiffness behavior, length, and surface condition are defined based on application requirements, supporting OEM drawings and repeat production.

Production and inspection follow defined procedures to support stable supply for industrial, outdoor, and utility fiberglass rod applications.

Fiberglass rods and graphite (carbon fiber) rods are both fiber-reinforced composite materials, but they differ fundamentally in mechanical behavior due to differences in fiber modulus, strain capacity, and failure mechanisms.

These material differences directly influence durability, stiffness, electrical properties, and cost considerations in industrial applications.

| Property | Fiberglass Rod (E-Glass) | Graphite / Carbon Fiber Rod |

|---|---|---|

| Density | 1.9–2.1 g/cm³ | 1.5–1.8 g/cm³ |

| Tensile Modulus | 20–30 GPa | 70–230 GPa |

| Tensile Strength | 500–900 MPa | 600–1500 MPa |

| Strain to Failure | ~2.5–4.5% | ~0.5–1.8% |

| Impact Resistance | High | Moderate to low |

| Electrical Conductivity | Non-conductive | Electrically conductive |

| Failure Mode | Progressive | Brittle |

Values represent commonly reported ranges in composite engineering references and ASTM mechanical test data.

Fiberglass rods exhibit lower stiffness but significantly higher strain capacity, allowing them to absorb impact energy and repeated bending without sudden fracture.

Failure typically occurs progressively, which improves damage tolerance in real-world handling and outdoor environments.

Graphite rods provide much higher stiffness due to the high modulus of carbon fibers, enabling lightweight designs with minimal deflection.

However, their lower strain tolerance results in brittle failure under impact, point loading, or misalignment.

Fiberglass rods are inherently non-conductive and resistant to moisture and corrosion, making them suitable for electrical, utility, and outdoor applications.

Graphite rods, while corrosion-resistant, are electrically conductive and require additional insulation considerations in certain environments.

From an OEM perspective, fiberglass rods generally offer lower raw material cost, wider processing tolerance, and more stable supply economics, particularly for larger diameters and long lengths.

Graphite rods involve higher material costs and stricter handling requirements, which can increase overall system cost despite weight savings.

| Design Priority | Recommended Material |

|---|---|

| Impact resistance and durability | Fiberglass Rod |

| Electrical insulation | Fiberglass Rod |

| Cost-sensitive OEM production | Fiberglass Rod |

| Maximum stiffness-to-weight ratio | Graphite Rod |

| Controlled loading environments | Graphite Rod |

Yes, fiberglass rods are commonly supplied in standard inch sizes such as 3/8, 1/2, and 3/4 inch.

Availability may vary by application and supply form, with custom diameters also supported.

Yes, fiberglass rods can be supplied in longer lengths such as 10 ft, depending on production and packaging requirements.

Length selection is typically based on application and handling considerations.

Neither is universally better; solid fiberglass rods are used for dimensional stability, while flexible fiberglass rods are designed to bend and recover under load.

The correct choice depends on stiffness requirements and how the rod is expected to perform in service.

Yes, fiberglass rods perform well in outdoor environments due to their resistance to moisture and corrosion.

They are widely used in utility, marker, and outdoor structural applications.

No, fiberglass rods are non-conductive.

This makes them suitable for electrical, utility, and insulation-related applications where metal rods are not appropriate.