Perché i clienti ci scelgono :

- Produttore-Controllo diretto

- Supporto ingegneristico

- Qualità costante

- Tempi di consegna affidabili

Carbon fiber sheets, plates, and panels are flat structural components manufactured from layered fiber-reinforced composite laminates.

Compared with traditional metal plates and panels, carbon fiber flat products offer a superior strength-to-weight ratio, excellent corrosion resistance, and greater design flexibility for engineered components.

In industrial and OEM applications, carbon fiber flat products are commonly supplied as sheets, plates, or panels, depending on thickness range, stiffness requirements, structural role, and machining intent.

Through controlled laminate design, fiber orientation, core integration (where applicable), and curing processes, these flat composites can be optimized for load distribution, dimensional stability, and downstream CNC machining or assembly.

Carbon fiber sheets, plates, and panels are widely used in aerospace structures, robotics systems, industrial equipment, tooling fixtures, and other applications where lightweight, rigid, and dimensionally stable flat components are required.

Our carbon fiber sheet and plate range includes three flat product categories.

Design decisions for this product are based on the mechanical properties and limitations of carbon fiber material, as outlined in our Carbon Fiber Material Overview.

Carbon fiber sheets are supplied as flat laminate stock for CNC cutting and lightweight structural components.

They are commonly used where low weight, dimensional stability, and efficient machining are required.

Carbon fiber plates are thicker flat laminates designed for higher stiffness and load-bearing applications.

They are typically selected for precision-machined structural parts requiring consistent strength.

Carbon fiber panels are application-oriented flat products supplied for structural or surface-integrated uses.

They are chosen when finished panel performance is required rather than raw machining stock.

Carbon fiber sheets and plates are often selected over traditional metal sheets when weight reduction, corrosion resistance, and structural efficiency are critical to system performance.

| Property | Carbon Fiber Sheets & Plates | Aluminum Plates (6061-T6) | Steel Plates (Carbon Steel) |

|---|---|---|---|

| Density | 1.5–1.6 g/cm³ | 2.7 g/cm³ | ~7.8 g/cm³ |

| Tensile Strength | 500–900 MPa (laminate-dependent) | ~310 MPa | 400–550 MPa |

| Elastic Modulus (Stiffness) | 70–140 GPa (directional) | ~69 GPa | ~200 GPa |

| Strength-to-Weight Ratio | Approx. 2.5–4× aluminum (application-dependent) | Baseline | Lower due to high density |

| Corrosion Behavior | No galvanic or atmospheric corrosion | Good corrosion resistance, susceptible to pitting | Requires coating for corrosion protection |

| Thermal Conductivity | 5–10 W/m·K | ~167 W/m·K | ~50 W/m·K |

| Fatigue Performance | Fiber-controlled, high fatigue resistance | Moderate | Moderate |

| Typical Engineering Use | Lightweight structural and machined components | General structural parts | Heavy-duty load-bearing structures |

Values shown are typical engineering reference ranges based on ASTM standards, ASM Handbooks, and industry material databases. Actual performance may vary depending on laminate design and application conditions.

Yes, carbon fiber sheets and plates can replace aluminum plates in many weight-sensitive applications.

They provide a higher strength-to-weight ratio and improved corrosion resistance.

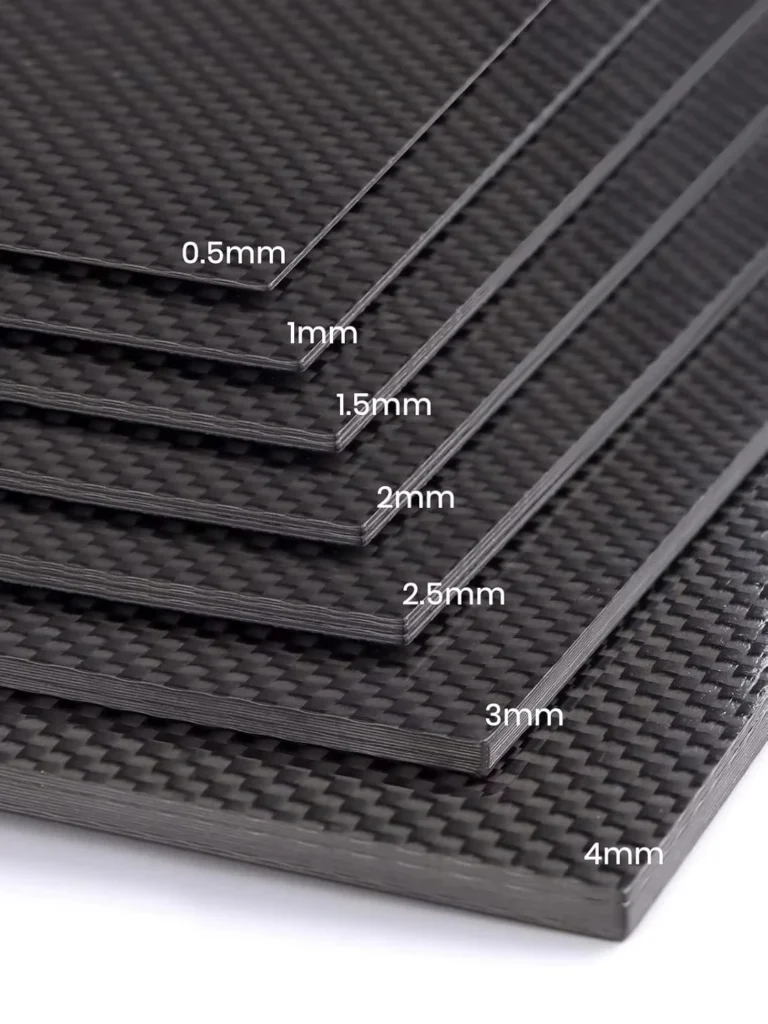

Carbon fiber sheets and plates are available in a wide range of thicknesses.

Custom thicknesses can be produced based on application requirements.

Carbon fiber sheets are thinner flat laminates, while carbon fiber plates are thicker and designed for higher stiffness.

The difference is mainly based on thickness and structural application, not material composition.

Carbon fiber plates are supplied as machining stock, while carbon fiber panels are application-oriented finished or semi-finished products.

Panels are chosen when integrated surface or enclosure performance is required.