Perché i clienti ci scelgono :

- Produttore-Controllo diretto

- Supporto ingegneristico

- Qualità costante

- Tempi di consegna affidabili

Carbon fiber parts and profiles refer to engineered composite components supplied as defined shapes rather than raw laminate materials.

Unlike flat sheets or tubes, these components are designed around geometry and load paths to improve stiffness, mounting efficiency, and system integration.

This category includes flat reinforcement strips, open-section channels, structural brackets, and molded forged carbon fiber parts, each serving a specific mechanical and assembly function.

Mechanical properties and structural limitations of carbon fiber material are explained in our Carbon Fiber Material Reference.

Our carbon fiber parts and profiles are supplied in defined geometries to support reinforcement, mounting, and structural integration across OEM assemblies.

Carbon fiber strips are flat composite profiles commonly used for structural reinforcement, stiffeners, and lightweight load-bearing elements.

They offer predictable bending stiffness and are frequently specified where straightness, thickness control, and bonding or CNC machining compatibility are required.

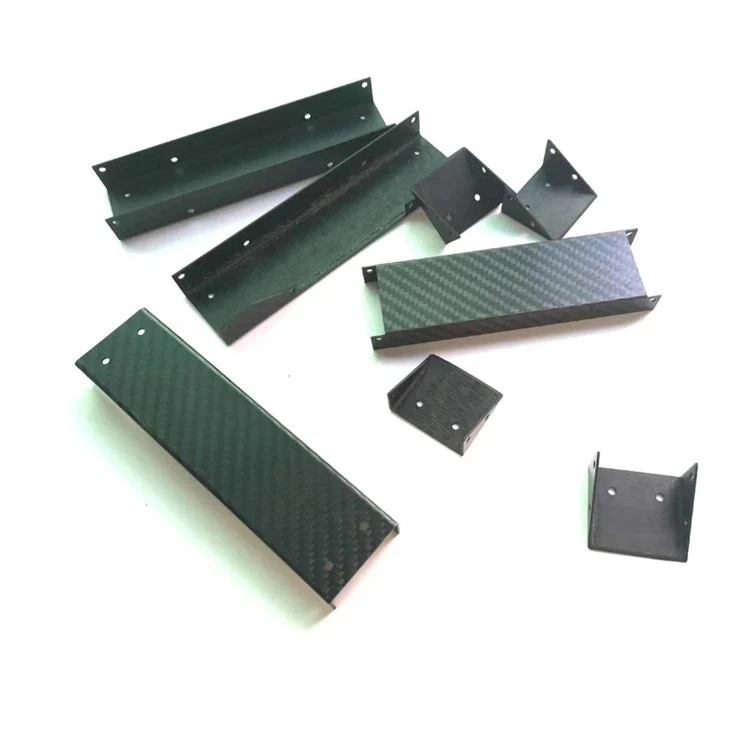

Forged carbon fiber parts are molded components produced from chopped carbon fiber and resin systems.

This form enables complex 3D geometries and consistent surface appearance, making it suitable for covers, housings, enclosures, and design-driven OEM components.

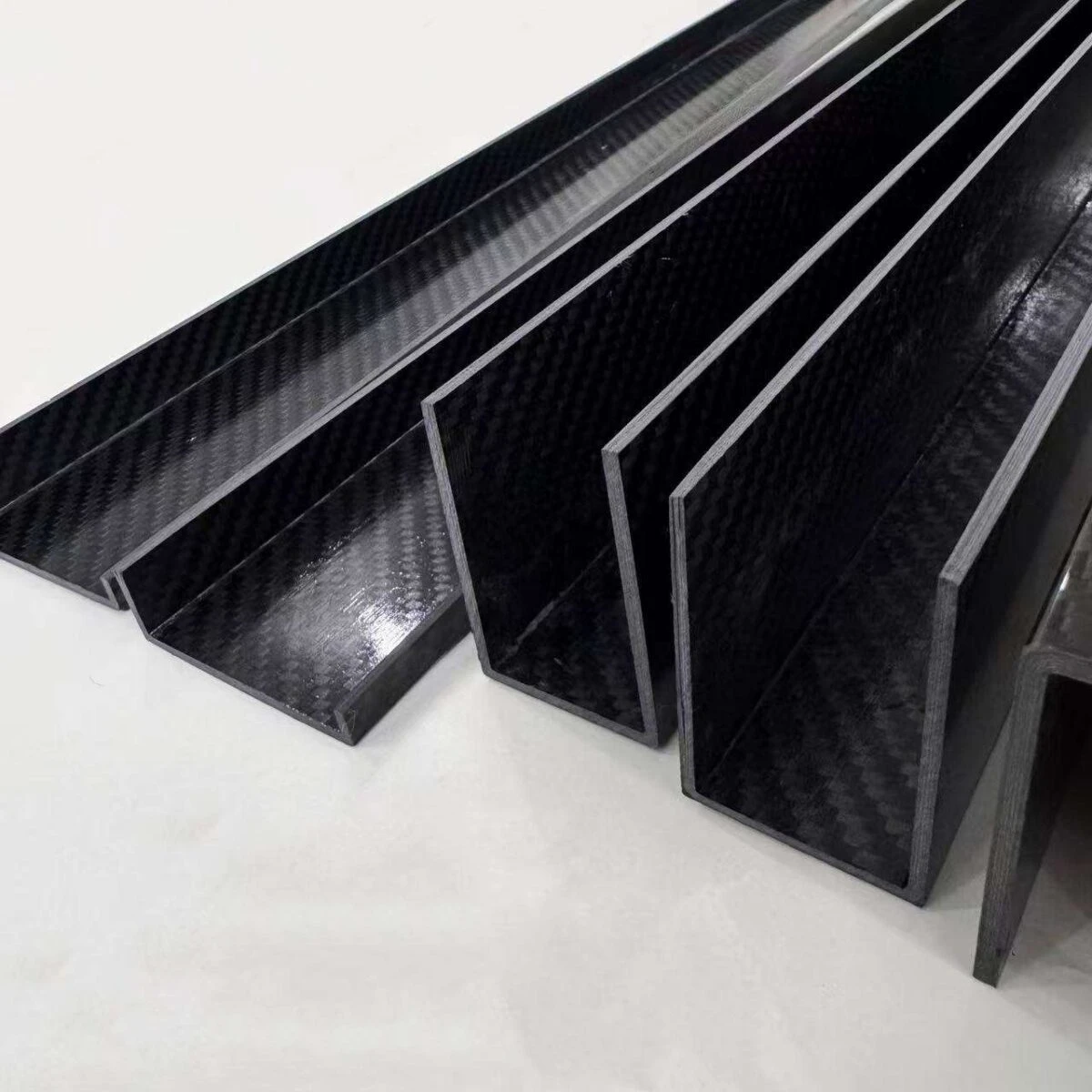

Carbon fiber channels are open-section composite profiles formed in U- or C-shaped geometries.

By increasing section height, channels deliver higher bending stiffness than flat laminates while maintaining accessibility for fastening, routing, and assembly.

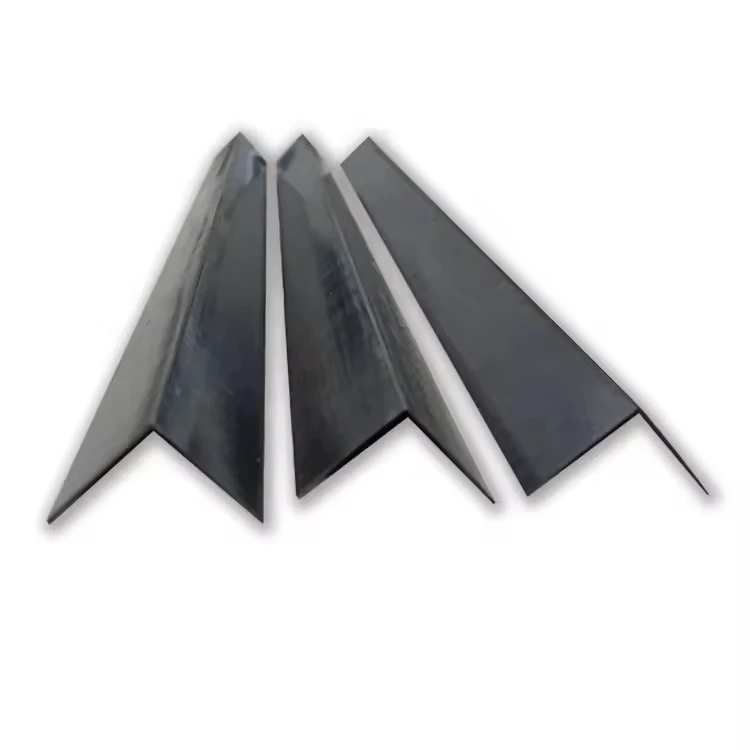

Carbon fiber brackets are structural mounting components designed for load transfer, positioning, and system integration.

They are typically engineered with local reinforcement around holes and edges to withstand fastening loads while maintaining a lightweight structure.

This comparison clarifies when carbon fiber components are selected as finished parts or profiles, rather than as semi-finished laminate materials.

| Comparison Focus | Carbon Fiber Parts & Profiles | Semi-Finished Laminates (Sheets / Tubes) |

|---|---|---|

| Definition Level | Geometry-defined components designed for direct use | Material forms supplied for further processing |

| Design Basis | Defined by function, load path, and integration method | Defined mainly by thickness, layup, and material grade |

| Typical Role | Structural reinforcement, mounting, and system integration | Raw structural material for machining or fabrication |

| Downstream Processing | Minimal secondary work required | Cutting, machining, and part definition required |

| Dimensional Control | Controlled at part or profile level | Depends on downstream processing accuracy |

| OEM Suitability | Suitable for repeatable assembly and scaling | More flexible for custom fabrication workflows |

| Selection Intent | Chosen when component-level consistency matters | Chosen when material-level flexibility is required |

Carbon fiber parts are engineered composite components defined by geometry and function rather than raw material form.

They are designed as finished or semi-finished components for structural reinforcement, mounting, or system integration.

Carbon fiber parts offer very high strength-to-weight performance when properly designed.

Their strength depends on fiber orientation, laminate design, and load direction rather than material thickness alone.

Yes, carbon fiber parts are worth it when weight reduction, stiffness, and long-term performance are critical.

They are commonly selected in OEM projects where lifecycle efficiency outweighs initial material cost.

Carbon fiber parts typically cost more upfront than metal or plastic alternatives.

However, reduced weight, corrosion resistance, and lower maintenance often improve total lifecycle cost.

Yes, many carbon fiber parts can be repaired depending on damage location and severity.

Localized cracks or delamination can often be restored using composite repair techniques.

Carbon fiber parts are more brittle under sharp impact and require careful design around fasteners.

They also involve higher material and manufacturing costs compared to conventional materials.