Perché i clienti ci scelgono :

- Produttore-Controllo diretto

- Supporto ingegneristico

- Qualità costante

- Tempi di consegna affidabili

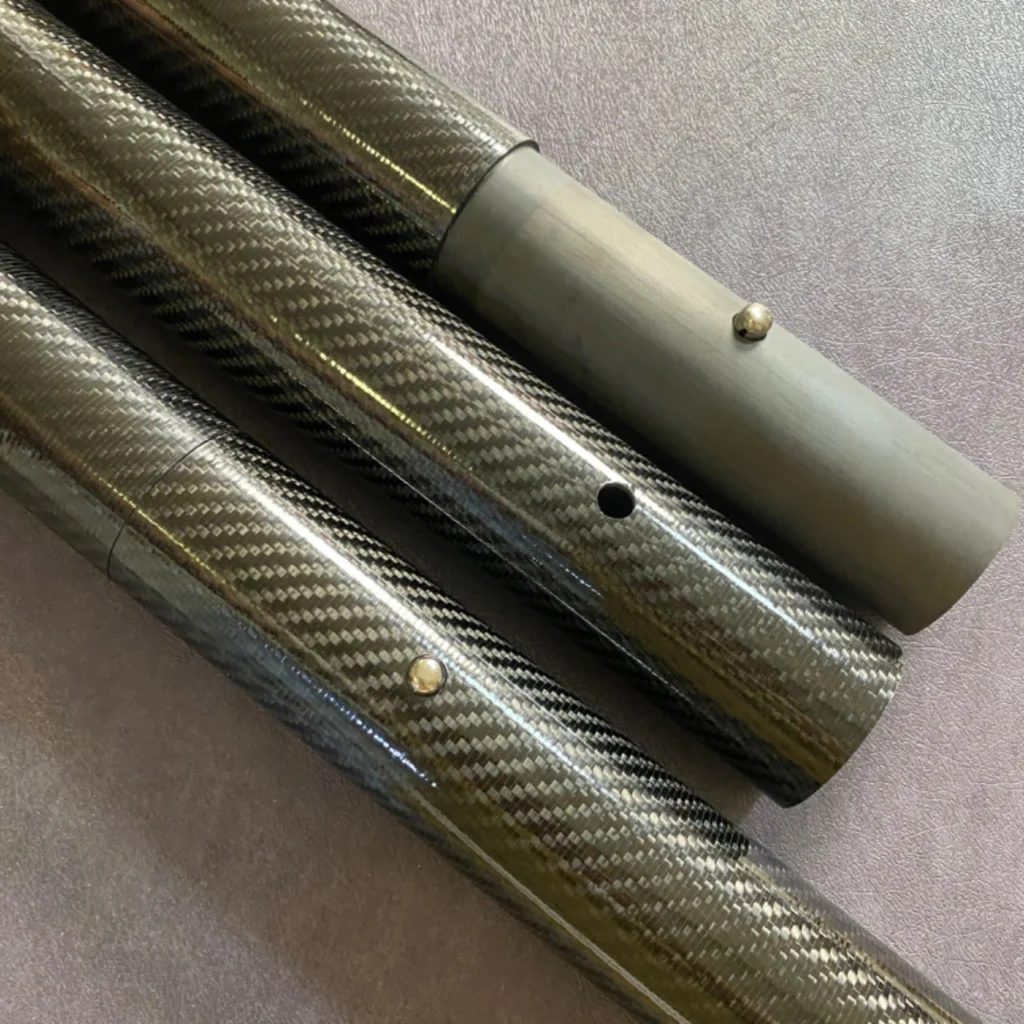

Telescoping carbon fiber tubes consist of multiple carbon fiber tubes, designed to slide inside one another and lock at variable lengths.

This structure enables tools to transition from a compact transport size to a long working reach within seconds.

Compared with aluminum or steel telescoping tubes, carbon fiber telescoping tubes provide:

These properties make telescoping carbon fiber tubes the structural foundation of many professional outdoor and field tools.

Engineering properties and material limitations relevant to this application are summarized in our Carbon Fiber Material Guide .

Carbon fiber is widely used in outdoor and field tools, including window cleaning poles, water fed poles, gutter cleaning poles, survey poles, inspection poles, and rescue reach poles, where lightweight strength and long-term durability are required.

Carbon fiber is widely used in window cleaning poles, water-fed poles, high-reach cleaning poles, exterior cleaning poles, and brush-mounted cleaning poles for façade maintenance.

These carbon fiber cleaning tools are designed for lightweight handling, corrosion resistance, and long-duration outdoor operation.

Outdoor maintenance equipment such as gutter cleaning poles, roof cleaning poles, solar panel cleaning poles, rooftop maintenance poles, and roof debris removal poles commonly incorporate carbon fiber.

High stiffness helps maintain control when working at full reach on elevated outdoor surfaces.

In agriculture and landscaping, carbon fiber is applied in fruit picking poles, pruning poles, tree trimmer poles, pole saws, and vegetation cutting poles.

The reduced weight and strength of carbon fiber improve efficiency in repetitive outdoor cutting and harvesting tasks.

Carbon fiber is commonly used in survey poles, measuring poles, measuring rods, GPS poles, GNSS poles, and construction layout poles for outdoor field measurement.

Dimensional stability and low thermal expansion help maintain accuracy in surveying and construction environments.

Emergency equipment such as rescue reach poles, safety extension poles, flood rescue poles, water rescue poles, and retrieval or hook extension poles frequently incorporate carbon fiber structures.

High strength and low weight improve maneuverability during time-critical outdoor rescue and safety operations.

Carbon fiber is applied in water sampling poles, environmental sampling poles, sensor mounting poles, and portable monitoring deployment poles.

These tools enable safe sampling and sensor installation in rivers, ponds, wetlands, and hazardous outdoor locations.

Field inspection equipment such as inspection poles, CCTV inspection poles, camera inspection poles, roof inspection poles, and bridge or structural inspection poles often use carbon fiber components.

These tools support non-contact inspection of buildings, infrastructure, and outdoor installations.

Carbon fiber is used in camera boom poles, microphone boom poles, field recording poles, and documentation extension poles for outdoor media capture and technical documentation.

The material provides rigidity and vibration damping for stable positioning in field conditions.

Municipal and facility maintenance tools such as maintenance extension poles, lighting maintenance poles, signage maintenance poles, and utility inspection poles rely on carbon fiber for extended reach and control.

These tools are commonly used in property maintenance, public utilities, and outdoor infrastructure servicing.

This section explains the most common telescopic pole connection and locking systems used in carbon fiber outdoor tools, focusing on stability, ease of adjustment, and field reliability.

Carbon fiber tube clamp systems use external mechanical clamps to secure telescopic sections through controlled radial compression.

They provide high locking force and excellent stiffness at full extension, making them suitable for tools carrying higher loads.

Twist lock systems rely on internal friction expansion activated by rotating the tube section.

This approach offers a clean exterior profile and reduced weight, ideal for tools requiring frequent adjustment and portability.

Spring button locking systems use a spring-loaded metal button engaging with pre-drilled holes to lock fixed length positions.

They offer fast, positive locking with clear tactile and visual confirmation.

Aluminum threaded connections use precision-machined threads or bonded threaded inserts to create rigid, load-stable joints.

They are selected when secure attachment and alignment are more critical than rapid adjustment.

The table below summarizes key design variables and typical applications for different telescopic pole connection systems.

| Connection System | Design Variables | Common Applications |

|---|---|---|

| Tube Clamp System | Clamp material, clamp width, compression force, tube overlap length | Inspection poles, Window cleaning poles, water-fed poles, gutter & roof cleaning tools, maintenance extension poles, outrigger poles , utility servicing equipment |

| Twist Lock System | Expansion sleeve material, friction surface design, torque range, tube wall thickness | camera boom poles, light-duty inspection tools |

| Spring Button Locking System | Button diameter, spring force, hole spacing, corrosion-resistant materials | Maintenance extension poles, utility tools, modular outdoor tool systems, access equipment |

| Aluminum Threaded Connection | Thread type, pitch, engagement length, surface treatment, bonding method | Sensor mounting poles, inspection & access tools, modular extension systems, maintenance equipment |

Carbon fiber outdoor tools are built using different composite product forms selected to meet specific structural and functional requirements.

Carbon fiber tubes are the primary structural components used in outdoor tools such as cleaning poles, inspection poles, survey poles, and maintenance extension tools.

They provide high bending stiffness at low weight, making them suitable for long-reach and overhead applications where stability and operator control are critical.

Carbon fiber tubes can be supplied in various diameters, wall thicknesses, and lengths to match different outdoor tool designs and load requirements.

→ Learn more about Carbon Fiber Tubes

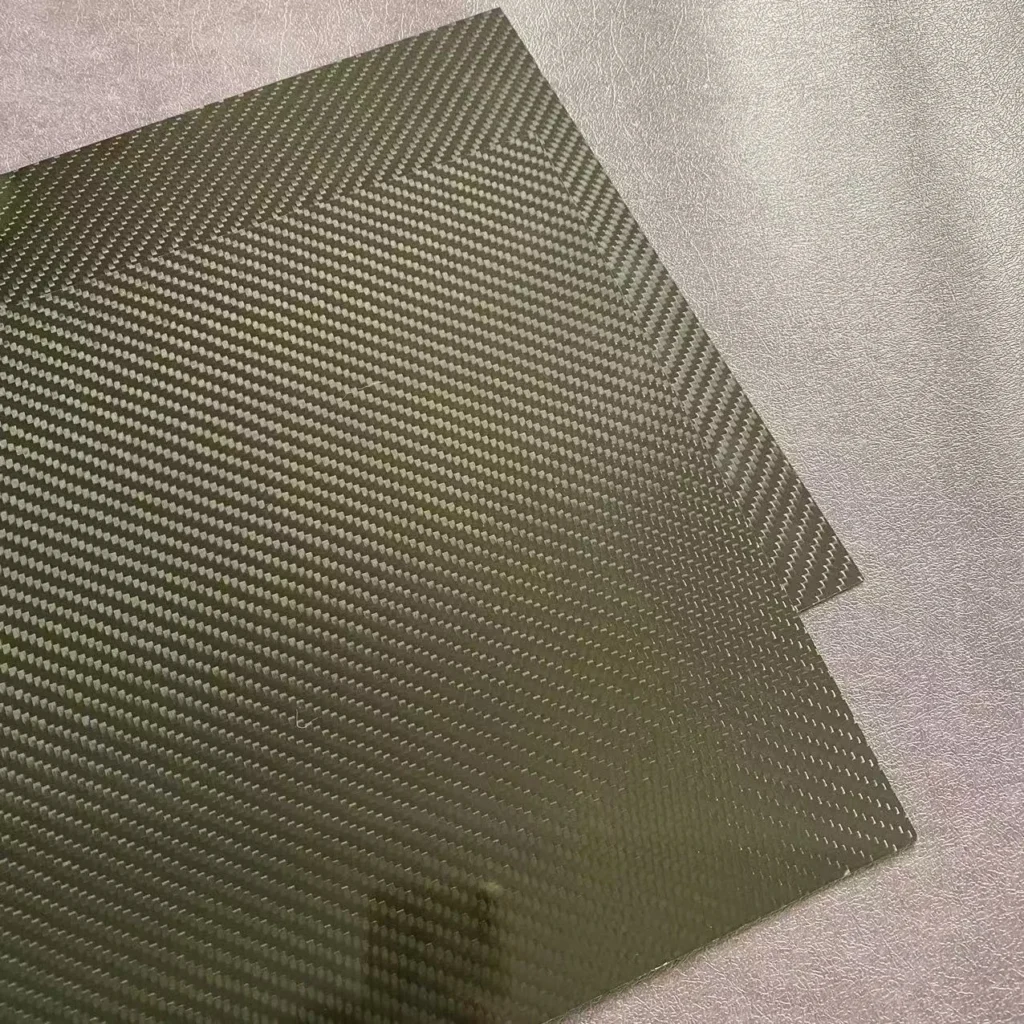

Carbon fiber sheets and plates are used in outdoor tools as mounting plates, housings, protective panels, and structural interfaces.

These flat composite products provide strength and rigidity while enabling precise machining for brackets, enclosures, and attachment points.

Sheets and plates are frequently integrated into outdoor tools that combine tubular structures with fixed mounting surfaces or protective covers.

→ Learn more about Carbon Fiber Seets & Plates

Carbon fiber rods are commonly used in measuring tools, alignment components, reinforcement elements, and support structures within outdoor and field equipment.

Their solid or semi-solid construction offers consistent stiffness and straightness, supporting applications where dimensional stability is essential.

Rods are often selected for outdoor tools that require compact strength, controlled deflection, or localized structural reinforcement.

→ Learn more about Carbon Fiber Rods

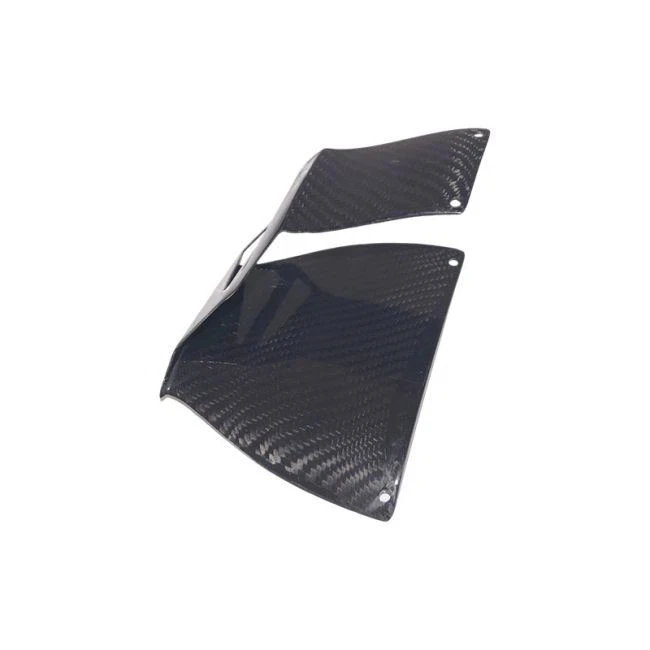

Custom carbon fiber parts are designed to meet application-specific functional and structural requirements in outdoor tools.

These parts include brackets, clamps, connectors, interfaces, and tool-specific components that cannot be achieved with standard profiles.

Custom fabrication allows outdoor tool manufacturers to optimize weight, stiffness, geometry, and integration for specific use cases and operating environments.

→ Learn more about Custom Carbon Fiber Parts

Carbon fiber is selected for outdoor tools because it delivers practical performance advantages in real field environments.

Carbon fiber reduces overall tool weight, helping operators work longer with less fatigue during overhead and long-reach tasks.

The high stiffness-to-weight ratio improves stability and control when tools are used at extended lengths.

Carbon fiber does not corrode, making it suitable for outdoor tools exposed to moisture, chemicals, and changing weather conditions.

Carbon fiber maintains performance under repeated loading and adjustment cycles common in outdoor and field use.

Carbon fiber allows stiffness, thickness, and geometry to be tailored for different outdoor tool requirements.

Application Background

A professional outdoor cleaning equipment manufacturer was developing a new generation of high-reach cleaning tools for window, façade, and solar panel maintenance.

The tools were required to operate at extended lengths while remaining easy to handle during prolonged outdoor use.

Key Requirements

Composite Solution

Custom carbon fiber composite tubes were supplied with optimized diameter, wall thickness, and fiber orientation to balance weight reduction and structural stiffness.

The tube design ensured stable handling while maintaining sufficient rigidity for long-reach cleaning applications.

Manufacturing Highlights

Result & Value

The final cleaning tools achieved significant weight reduction while maintaining stability at extended working lengths, improving efficiency and comfort during outdoor cleaning operations.

Case 2: Carbon Fiber Poles for Inspection & CCTV Equipment

Application Background

An inspection equipment supplier required lightweight yet rigid pole systems to support cameras and sensors used for building, roof, and infrastructure inspections.

Maintaining image stability and precise positioning at height was a critical design challenge.

Key Requirements

Composite Solution

Carbon fiber tubes and custom interface components were designed to support camera loads while minimizing deflection and vibration.

Structural stiffness was tuned through laminate design to improve inspection accuracy at extended reach.

Manufacturing Highlights

Result & Value

The inspection poles delivered improved image stability and handling, enabling more accurate inspections while reducing setup time and operator effort in the field.

Case 3: Carbon Fiber Components for Utility & Maintenance Tools

Application Background

A utility maintenance tool provider was developing extension tools for lighting, signage, and facility maintenance in outdoor environments.

The tools were required to withstand frequent use, environmental exposure, and repeated adjustment cycles.

Key Requirements

Composite Solution

A combination of carbon fiber tubes and custom carbon fiber parts was used to construct lightweight yet durable extension tools.

Connection points and interfaces were reinforced to ensure reliable performance under daily field use.

Manufacturing Highlights

Result & Value

The final tools demonstrated extended service life, reduced maintenance requirements, and improved handling compared with traditional metal alternatives.

Carbon fiber is used in outdoor tools because it combines low weight, high stiffness, and corrosion resistance.

These properties improve handling, control, and durability in long-reach and field-use applications.

Yes. Carbon fiber does not rust and performs well in wet, coastal, and chemically exposed environments.

This makes it suitable for outdoor tools used in cleaning, inspection, maintenance, and field operations.

Compared with aluminum or steel, carbon fiber tools are significantly lighter while maintaining high stiffness.

This reduces operator fatigue and improves control, especially for extended or overhead outdoor work.

Yes. Carbon fiber structures are well suited for long-reach tools because stiffness, wall thickness, and tube geometry can be engineered to control deflection at extended lengths.

Carbon fiber outdoor tools can be integrated with tube clamp systems, twist lock systems, spring button locks, or threaded connections.

The selection depends on load requirements, adjustment frequency, and operating conditions.

Yes. Carbon fiber exhibits good fatigue resistance and maintains performance under repeated loading, extension, and adjustment cycles common in outdoor and field use.

Yes. Carbon fiber tools can be designed with reinforced sections, threaded inserts, or custom interfaces to support tool heads, sensors, cameras, and other attachments.

Key considerations include load conditions, working length, environmental exposure, connection design, and user operation requirements.

These factors help determine the appropriate structure and material configuration.

We provide a complete portfolio of composite products for outdoor tools applications: