Real-World Applications Across Industries

Carbon Fiber Applications Overview

| Application Area | Typical Carbon Fiber Products | Key Performance Benefits |

|---|---|---|

| Équipement sportif | Shafts, frames, tubes, plates, rods | Lightweight, stiffness control, vibration damping |

| Outils d'extérieur | Telescopic poles, extension tubes | Long reach, reduced fatigue, corrosion resistance |

| Drones et UAV | Frames, arms, tubes, CNC plates | Weight reduction, vibration stability, flight efficiency |

| Robotique et automatisation | Robot arms, gantry beams, structural plates | Low inertia, high stiffness, positional accuracy |

| Automobiles et voitures | Body parts, hoods, seats, PDR tools | Weight reduction, structural efficiency, durability |

| Industrie et services publics | Inspection poles, support arms, composite tubes | Safe handling, corrosion resistance, long service life |

| Protection et sécurité | Guards, covers, handles, panels | Impact resistance, structural reliability |

Carbon Fiber in Sports Equipment

Carbon fiber is extensively used in sports equipment because performance depends on strength-to-weight ratio, stiffness control, straightness, and vibration behavior. In most cases, carbon fiber is the primary load-bearing structure rather than a cosmetic layer.

Common sports equipment that uses carbon fiber

Carbon fiber is widely used in:

-

Shafts and tubes for golf, hockey, lacrosse, and cue sports

-

Archery components such as arbres à flèches and stabilizer rods

-

Racket frames for tennis, badminton, squash, and padel

-

Paddle sports equipment including SUP paddles and kayak paddles

-

Water sports components such as mâts de planche à voile, booms, and hydrofoil structures

-

Marine and training equipment including poteaux stabilisateurs and slalom poles

Why carbon fiber is used in sports

Designers use carbon fiber to:

-

Tune stiffness and flex profiles for specific disciplines

-

Reduce weight without sacrificing strength

-

Improve vibration damping and control

-

Maintain straightness and consistency over repeated use

Typical carbon fiber forms used in sports

-

Tubes for frames, shafts, and structural members

-

Sheets and plates for boards, panels, and CNC-machined parts

-

Rods for axial stiffness and controlled flex

-

Custom parts and profiles for OEM integration

Carbon Fiber for Outdoor Tools

Outdoor tools are one of the most practical uses of carbon fiber, especially where long reach and low operator fatigue are essential. Carbon fiber is commonly used as telescopic tubing in tools designed for cleaning, inspection, rescue, and field operations.

Outdoor tools commonly made with carbon fiber

-

Water fed poles and high-reach cleaning poles

-

Gutter, roof, and solar panel cleaning tools

-

Fruit picking, pruning, and pole saw systems

-

Survey poles and GPS / GNSS measuring rods

-

Rescue and safety reach poles

-

Inspection camera poles for roofs, bridges, and structures

Key design requirements for outdoor tools

-

High stiffness at full extension

-

Low weight for overhead or prolonged use

-

Secure locking systems such as clamps, twist locks, or spring buttons

-

Corrosion resistance in wet or outdoor environments

Why carbon fiber is preferred

Compared with aluminum or steel, carbon fiber poles offer:

-

Lower weight for improved ergonomics

-

Better stiffness-to-weight ratio at long lengths

-

Improved durability in harsh environments

Carbon Fiber in Drones & UAV Systems

Carbon fiber is a core structural material in drones and UAV platforms because it allows designers to reduce mass while maintaining frame rigidity, alignment accuracy, and vibration stability.

Common carbon fiber UAV components

-

Drone frames and airframe plates

-

Structural arms, booms, and tubes

-

Mounting plates and reinforcement panels

-

CNC-machined components for motors, cameras, and gimbals

-

Parts used in DIY and custom UAV builds

Why carbon fiber is used in UAVs

Carbon fiber helps improve:

-

Flight time and payload capacity

-

Structural stiffness with minimal weight

-

Vibration control for sensors and imaging systems

-

Dimensional stability under dynamic loads

Typical carbon fiber forms in UAVs

-

Tubes for arms, booms, and landing structures

-

Sheets and plates for CNC-cut frame components

-

Bonded or integrated assemblies for platform-level systems

Carbon Fiber for Robotics & Automation

In robotics and automation, carbon fiber is used to improve speed, accuracy, and energy efficiency. Reducing moving mass while maintaining stiffness allows robotic systems to operate faster and more precisely.

Robotics applications using carbon fiber

-

Robot arms and long-reach links

-

Gantry beams and automation frames

-

Structural plates and panels

-

Mounting interfaces and reinforced joints

Key engineering benefits

Carbon fiber enables:

-

Lower inertia for faster acceleration and deceleration

-

Reduced deflection for improved positional accuracy

-

Better vibration behavior at high cycle rates

-

Long-term dimensional stability in industrial environments

Common carbon fiber product forms

-

Tubes for arms and structural members

-

Sheets and plates for CNC machining

-

Bonded assemblies with metal inserts or interfaces

Carbon Fiber in Cars & Automotive Applications

Automotive applications use carbon fiber to reduce weight while maintaining structural performance. Beyond racing, carbon fiber is increasingly used in functional components, interior structures, and specialized tools.

Automotive components made from carbon fiber

-

Body panels and structural parts

-

Hoods and exterior components

-

Seat structures and interior reinforcements

-

Exhaust tips and trim components

-

Paintless dent repair (PDR) tools

Why carbon fiber is used in automotive design

-

Weight reduction improves handling and efficiency

-

High stiffness supports structural integrity

-

Fatigue resistance improves long-term reliability

-

Complex shapes can be produced for low-volume OEM projects

In many automotive applications, carbon fiber components can reduce weight by 30-60% compared to steel or aluminum while maintaining comparable structural performance.

Carbon Fiber for Industrial & Utility Use

In industrial and utility environments, carbon fiber is selected for safe handling, corrosion resistance, and structural reliability, especially in portable or long-reach equipment.

Typical industrial and utility applications

-

Inspection poles and camera positioning systems

-

Support arms and mounting structures

-

Portable poles for field operations

-

Composite tubes and rods for structural use

Carbon fiber vs fiberglass in utility applications

-

Carbon fiber offers higher stiffness and lower weight

-

Fiberglass is used when electrical insulation is required

-

Material selection depends on safety, environment, and load requirements

Carbon Fiber in Protective & Safety Products

Protective and safety applications use carbon fiber as a functional structural material, not merely for appearance. Performance, reliability, and consistency over time are critical.

Common protective and safety products

-

Impact and abrasion guards

-

Structural covers and housings

-

Reinforced handles and grips

-

Protective panels for equipment and users

Why carbon fiber is used

-

High strength with controlled weight

-

Dimensional stability under load

-

Reliable performance over long service life

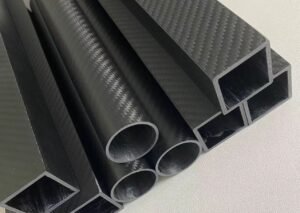

Choosing the Right Carbon Fiber Form

Selecting the correct carbon fiber form depends on the structural role, not just the product name:

-

Tubes: bending and torsion structures such as arms, poles, and frames

-

Sheets & plates: flat stiffness and CNC-machined components

-

Rods: axial stiffness, straightness, and reinforcement

-

Custom parts & assemblies: complex geometry and OEM integration

OEM & Manufacturing Perspective

The applications described above reflect how carbon fiber is used in real-world OEM manufacturing, where material selection is driven by performance requirements, structural reliability, and long-term service life—not appearance alone.

In practical production, factors such as fiber orientation, laminate design, wall thickness, and interface integration directly affect stiffness, fatigue behavior, and dimensional stability. These considerations are especially critical in applications involving long reach, high cycle rates, or dynamic loading.

Understanding carbon fiber by application—not just by material properties—helps engineers, buyers, and product teams make more informed decisions when developing lightweight structural components for demanding environments.

Composite Products

We provide a complete portfolio of composite products :