Pourquoi les clients nous choisissent :

- Fabricant-Contrôle direct

- Soutien à l'ingénierie

- Une qualité constante

- Délai de livraison fiable

Fiberglass tubes, also known as FRP tubes or fiberglass tubing, are composite profiles engineered for structural, electrical, and corrosion-resistant applications.

They combine high mechanical strength, low weight, and long-term durability, making them a reliable alternative to traditional metal tubing in industrial environments.

Compared with steel or aluminum tubes, fiberglass tubes provide superior corrosion resistance, electrical insulation, and reduced maintenance requirements.

We manufacture standard and custom fiberglass tubes in a wide range of diameters, wall thicknesses, and resin systems to support OEM, wholesale, and industrial projects.

Our fiberglass tubes are classified by manufacturing process and profile geometry.

Pultruded fiberglass tubes are produced through a continuous pultrusion process, delivering a constant cross-section with high fiber volume content.

They are typically selected for applications requiring consistent mechanical properties, dimensional stability, and reliable axial load performance in structural and electrical systems.

Filament wound fiberglass tubes are designed for applications where hoop strength, pressure resistance, or torsional performance is critical.

By adjusting fiber winding angles and laminate structure, these tubes can be engineered to meet specific mechanical load paths and operating conditions.

Round fiberglass tubes provide uniform strength distribution and straightforward integration into structural assemblies.

They are commonly used where balanced mechanical performance, ease of installation, and compatibility with standard fittings are required.

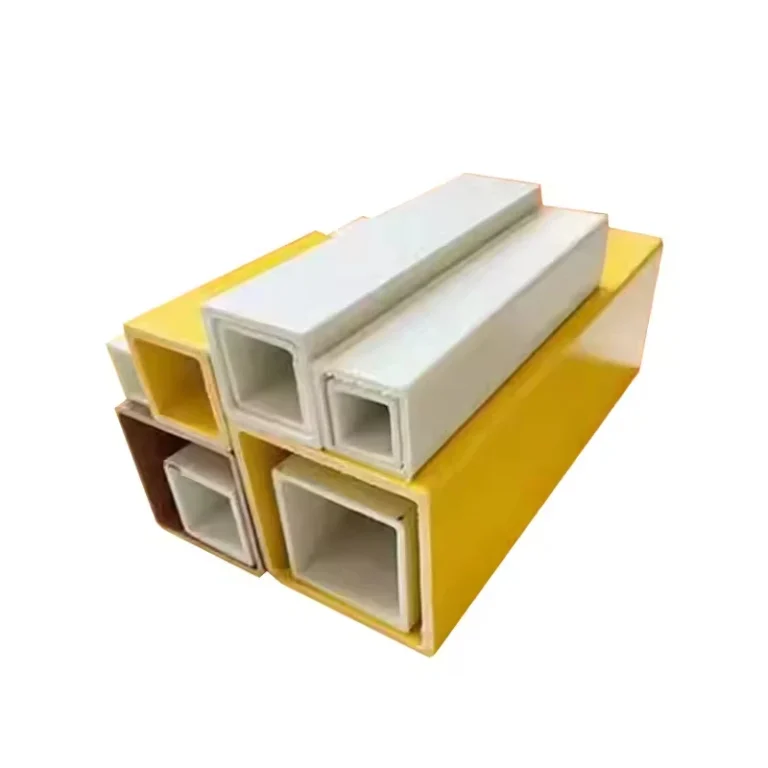

Square fiberglass tubes offer improved rotational stability and flat mounting surfaces compared to round profiles.

They are often chosen for frames, platforms, and structural assemblies where alignment, rigidity, and connection accuracy are important.

Rectangular fiberglass tubes are suitable for applications requiring directional stiffness and optimized load distribution.

Their profile geometry allows engineers to tailor structural performance for beams, supports, and components subjected to asymmetric loads.

Custom fiberglass tubes are manufactured to meet specific dimensional, mechanical, and environmental requirements.

Customization options may include tube geometry, wall thickness, fiber reinforcement design, resin system selection, and surface finish to support OEM and engineered applications.

Fiberglass tubes are used across a wide range of structural, industrial, and outdoor applications.

This overview provides a concise reference of our fiberglass tube manufacturing capabilities for industrial and OEM applications.

| Capability Area | Description |

|---|---|

| Procédés de fabrication | Pultrusion and filament winding processes selected based on structural and application requirements |

| Diameter Range | Flexible diameter configurations to support standard and custom fiberglass tube designs |

| Wall Thickness Control | Controlled laminate structure to ensure consistent wall thickness and repeatable performance |

| Length Options | Standard lengths and cut-to-length production supported |

| Resin Systems | Polyester, vinyl ester, and epoxy resin systems available |

| Fiber Reinforcement | E-glass and S-glass reinforcement options |

| Dimensional Tolerance | Controlled dimensional tolerances for reliable assembly and fit |

| Custom Production | OEM and custom fiberglass tube manufacturing supported |

Fiberglass tubes are selected for applications where durability, electrical insulation, and environmental resistance are as critical as structural performance.

Fiberglass tubes are inherently non-conductive, making them suitable for electrical structures, cable supports, and insulation-critical environments.

Unlike metal tubing, fiberglass tubes resist corrosion, moisture, and chemical exposure, supporting long-term use in outdoor and harsh operating conditions.

Fiberglass tubes provide reliable structural strength while maintaining excellent impact resistance, reducing the risk of brittle failure in industrial and outdoor applications.

Controlled manufacturing processes ensure consistent dimensions and mechanical properties, supporting repeatable performance across production batches and OEM supply programs.

Carbon fiber and fiberglass are both widely used reinforcement materials in composite structures, but they are selected for different engineering priorities.

Understanding their practical differences helps engineers and buyers choose the appropriate material based on performance, durability, and cost considerations.

Carbon fiber is typically specified when maximum stiffness and weight reduction are primary design drivers.

Its high modulus allows structures to achieve superior stiffness at minimal weight, which is critical in performance-driven applications.

Fiberglass, by contrast, is commonly selected for balanced structural performance, offering good strength, excellent toughness, and strong resistance to environmental exposure.

It is widely used where durability, electrical insulation, and long service life are required.

Carbon fiber composites generally require tighter control over fiber orientation, consolidation quality, and curing conditions.

These requirements support high-performance outcomes but increase manufacturing complexity and cost.

Fiberglass composites allow more forgiving processing windows and are less sensitive to minor manufacturing variation.

This makes fiberglass well suited for scalable production, outdoor use, and applications requiring consistent long-term reliability.

| Aspect | Carbon Fiber | Fiberglass |

|---|---|---|

| Key advantage | High stiffness-to-weight ratio | Durability and versatility |

| Cost level | High | Moderate to low |

| Impact resistance | Lower | Excellent |

| Electrical insulation | Conductive | Non-conductive |

| Typical use focus | Performance-critical structures | Durable industrial and outdoor structures |

Carbon fiber is commonly used in UAV systems, robotics, and lightweight mobility structures where performance efficiency justifies higher cost and tighter control.

Fiberglass is widely applied in industrial equipment, electrical systems, marine structures, agriculture, and outdoor installations where durability, insulation, and cost-effective production are priorities.

Yes, fiberglass tubes are widely used in structural applications where lightweight strength, corrosion resistance, and dimensional stability are required.

They are commonly applied in frames, supports, and load-bearing systems designed for long-term use.

Yes, fiberglass tubes perform well in outdoor environments due to their resistance to moisture, corrosion, and UV exposure.

This makes them suitable for agricultural, marine, infrastructure, and other outdoor applications.

No, fiberglass tubes are non-conductive and provide excellent electrical insulation.

They are often used in electrical structures, cable supports, and insulation-critical environments.

Yes, fiberglass tubes can be manufactured in custom diameters, wall thicknesses, lengths, and resin systems.

Custom production supports OEM projects and application-specific requirements.

Fiberglass tubes offer corrosion resistance, electrical insulation, and lower maintenance compared to metal tubes.

They are often selected where environmental resistance and long service life are more important than maximum stiffness.