Pourquoi les clients nous choisissent :

- Fabricant-Contrôle direct

- Soutien à l'ingénierie

- Une qualité constante

- Délai de livraison fiable

Carbon fiber rods are rigid composite profiles manufactured by consolidating carbon fiber reinforcement with a thermoset resin system into a straight rod form.

They are valued for their high strength-to-weight ratio, stiffness, and dimensional stability, and are widely used in industrial and OEM applications where lightweight structural performance is critical.

In an engineering context, carbon fiber rods are supplied as structural components rather than finished consumer products.

Material-level performance data and engineering considerations for carbon fiber are detailed in our Référence des matériaux en fibre de carbone.

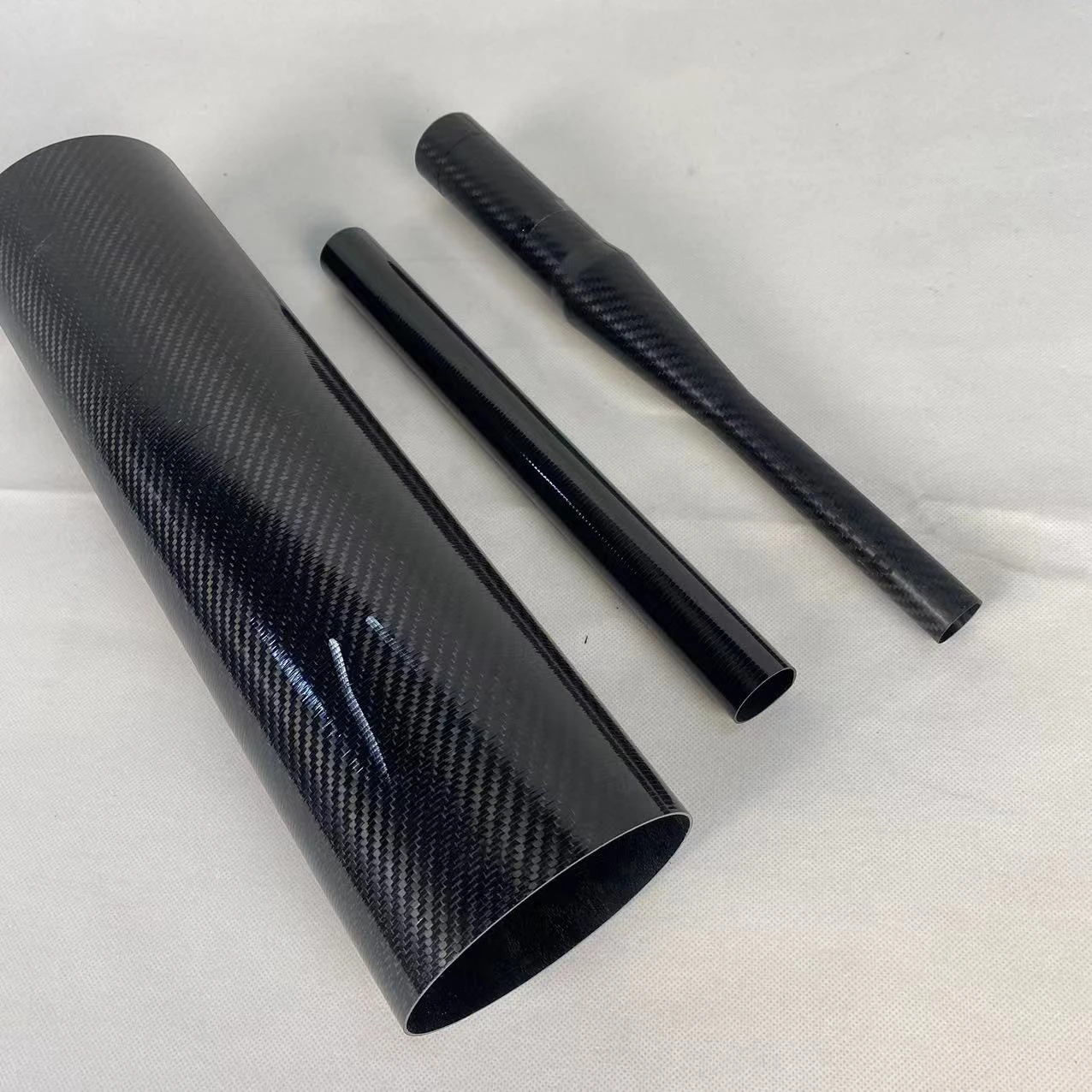

Carbon fiber rods are supplied in multiple structures to support different OEM and application requirements.

Solid carbon fiber rods provide maximum stiffness and compressive strength for load-bearing and structural applications.

They are supplied with consistent diameters for cut-to-length use and secondary machining in OEM assemblies.

Hollow carbon fiber rods are designed to reduce weight while maintaining high bending stiffness.

They are commonly used in lightweight structures requiring efficient strength-to-weight performance.

Carbon fiber square rods offer anti-rotation geometry and improved torsional stability.

The square profile supports precise alignment in frames, guides, and structural interfaces.

Carbon fiber connecting rods act as structural linking elements in industrial assemblies, not automotive engine components.

They provide lightweight stiffness and corrosion resistance for custom mechanical connections.

Custom carbon fiber rods are manufactured to customer-defined specifications, including diameter, length, structure, and fiber layout.

They are supplied for OEM and project-based applications requiring tailored mechanical performance and dimensional control.

Carbon fiber rods can be supplied in standard sizes or manufactured to specification for OEM and custom applications.

| Specification Item | Standard Capability |

| Carbon Fiber Rod Type | Solid / Hollow / Square / Custom |

| Diameter / Size | Ø0.8 mm – Ø50 mm (square sizes available) |

| Length Options | Up to 3000 mm (cut-to-length supported) |

| Construction | Unidirectional or multi-layer composite |

| Manufacturing Method | Pultrusion / Precision lay-up |

| Dimensional Tolerance | ±0.1 mm (typical, tighter on request) |

| Surface Finish | Smooth / Sanded / Coated |

| Supply Form | Straight rods, batch supplied |

Carbon fiber rods are used as functional structural elements in engineered assemblies requiring stiffness, geometry control, and lightweight performance.

Carbon fiber rods for RC planes are used as structural and reinforcement elements to maintain rigidity while minimizing weight.

Carbon fiber rods for kites, including kite carbon fiber rods, are applied in kite frame structures where flexibility and strength must be balanced.

Carbon fiber rods for guitar necks are used as reinforcement components to improve stiffness and long-term dimensional stability.

Flexible carbon fiber rods are applied in controlled-flex designs where limited bending is required without permanent deformation.

Carbon fiber rods are supplied with a focus on OEM consistency, dimensional control, and reliable production support.

| OEM Capability | Benefit for Your Carbon Fiber Rod Project |

|---|---|

| OEM-Focused Manufacturing | Stable quality and batch-to-batch consistency for long-term supply |

| Standard & Custom Options | Solid, hollow, square, and custom rods made to specification |

| Dimensional Control | Controlled diameters and straightness suitable for machining |

| Flexible Production Support | Prototypes, small batches, and volume orders supported |

Yes. Our carbon fiber rods are supplied for OEM and project use, with cut-to-length and specification-based options available rather than retail stock sizes.

The key difference lies in stiffness versus toughness.

Carbon fiber rods provide high stiffness and strength-to-weight ratios, making them ideal for structural use. Kevlar contributes impact resistance and fatigue toughness but lacks the rigidity required for most rod applications.

Yes. Carbon fiber rods are commonly used in RC plane structures, kite frames, and guitar neck reinforcement, where stiffness, weight control, or controlled flexibility is required.

No. We supply carbon fiber rods through direct OEM and wholesale channels, not via local retail stores or consumer marketplaces.

A carbon fiber rod is a rigid composite structural component manufactured from carbon fiber reinforcement and a resin matrix.

In industrial use, carbon fiber rods are supplied as straight solid or hollow profiles designed to carry load, maintain alignment, or reinforce assemblies, rather than as finished consumer products.

The tensile strength of a carbon fiber rod typically ranges from 600 to 1,200 MPa, depending on fiber grade, layup, and manufacturing method.

Its mechanical performance is determined by fiber orientation and resin system, with unidirectional structures optimized for axial loading and multi-layer constructions used where bending or stability is required.

Carbon fiber rods provide comparable structural strength to steel while operating at a significantly lower material density.

Typical carbon fiber composites have a density of approximately 1.5–1.6 g/cm³, compared to 7.8 g/cm³ for carbon steel, which allows engineers to achieve required stiffness and load capacity with reduced mass when designs are properly engineered.

Carbon fiber rods offer a combination of controlled stiffness, corrosion resistance, and dimensional stability.

These characteristics make them suitable for structural reinforcement, precision assemblies, and OEM applications where consistent geometry, predictable performance, and long-term durability are required.