Pourquoi les clients nous choisissent :

- Fabricant-Contrôle direct

- Soutien à l'ingénierie

- Une qualité constante

- Délai de livraison fiable

Carbon fiber composites are widely used in drones and UAVs because they deliver high stiffness at low weight, strong fatigue resistance, and excellent dimensional stability—helping aircraft maintain alignment, reduce vibration, and extend service life in harsh outdoor conditions.

In drone structures, carbon fiber is commonly supplied as:

For OEM projects, laminate design (fiber type, orientation, thickness) can be tuned for impact resistance, torsional rigidity, and vibration behavior—not just “stronger.”

The use of carbon fiber in this application is driven by its mechanical performance and structural characteristics, which are explained in our Référence des matériaux en fibre de carbone.

Below are the primary carbon fiber product types commonly used in UAV and drone platforms, covering structural frames, arms, and precision components.

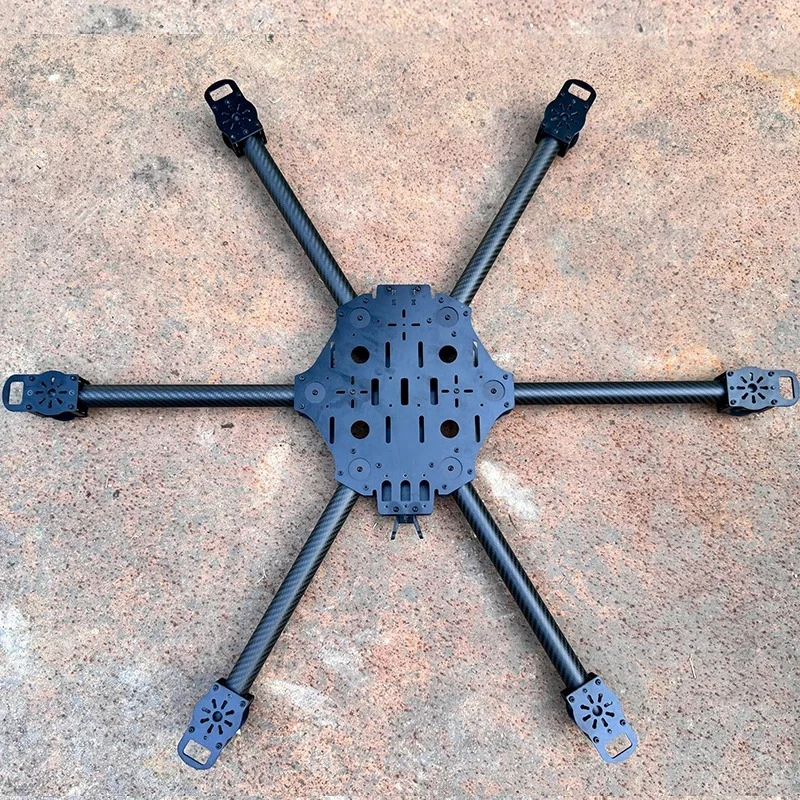

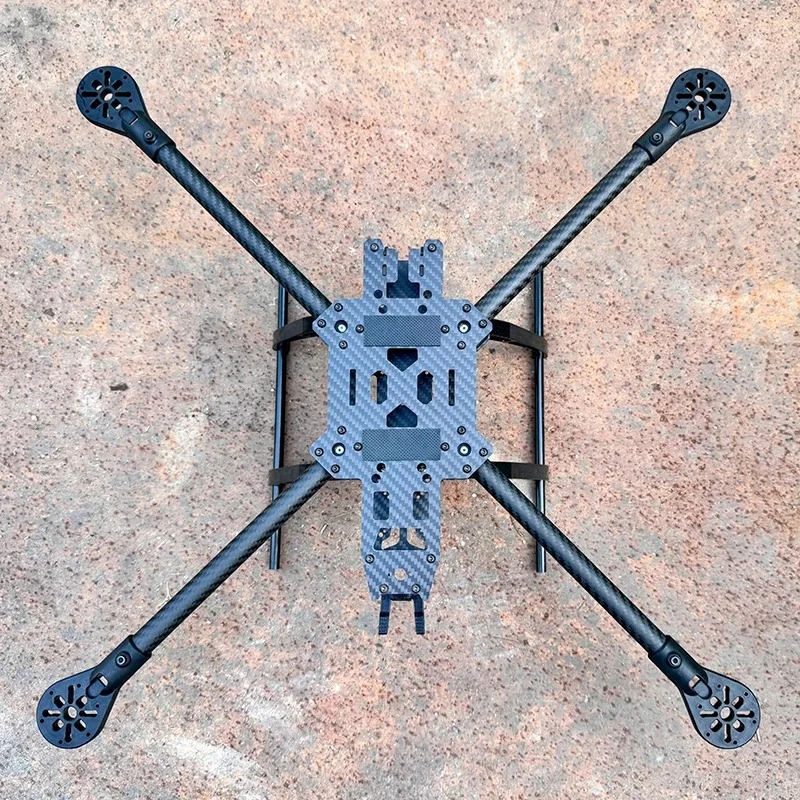

This category includes carbon fiber drone frames and structural body components used as the primary load-bearing structure of UAV and drone platforms.

Typical products include frame plates, body panels, arm plates, and integrated airframe structures designed for stiffness, alignment stability, and weight reduction.

Carbon fiber drone propellers, blades, and prop components are used in applications where higher stiffness and reduced deformation are required.

Suitability depends on rotational speed, balance tolerance, impact risk, and safety requirements, and should be evaluated at the design stage.

This category covers carbon fiber UAV structural components used across industrial and commercial UAV platforms.

Common forms include arms, booms, tubes, mounting plates, and reinforcement parts supplied as individual components or structural sub-assemblies.

DIY carbon fiber drone components are supplied for prototyping, custom builds, and development-stage UAV projects.

These typically include carbon fiber plates, tubes, and cut-to-size parts that allow engineers and developers to configure custom drone structures based on specific performance targets.

Below is a practical overview of key design variables and how they influence carbon fiber component selection across different UAV and drone applications.

| Design Variable | What It Affects | Typical UAV / Drone Applications |

| Weight target | Flight time, payload efficiency, agility | FPV racing drones, long-endurance UAVs |

| Bending stiffness | Structural stability and frame deflection | Carbon fiber drone frames, frame plates |

| Torsional rigidity | Control response and arm twist under load | UAV arms, booms, carbon fiber tubes |

| Laminate orientation | Directional strength and vibration behavior | Frame plates, arm structures, support members |

| Plate thickness | Impact resistance and service durability | Drone frame plates, mounting plates |

| Tube diameter & wall thickness | Load capacity and bending resistance | Carbon fiber UAV arms, landing struts |

The following carbon fiber product forms are commonly used to manufacture structural and functional components in drone and UAV platforms.

Carbon fiber tubes are used as lightweight structural members in UAV platforms.

Typical applications include drone arms, booms, landing struts, and support structures, where bending and torsional performance are critical.

→ En savoir plus sur les tubes en fibre de carbone

Carbon fiber sheets and plates are widely used for CNC machining flat structural components in drones and UAVs.

They are commonly applied to drone frame plates, mounting panels, reinforcement plates, and equipment decks where stiffness and flatness are required.

→ En savoir plus sur les sièges et plaques en fibre de carbone

Machined carbon fiber parts are used for precision interfaces and assembly features in drone structures.

Common examples include motor mounts, camera plates, gimbal components, brackets, and spacers, produced to drawing-based tolerances.

→ Learn more about Custom Solutions

For platform-level projects, multiple carbon fiber product forms can be combined into bonded or integrated sub-assemblies.

This approach is often used for carbon fiber UAV frames and mission-specific structural modules requiring alignment stability.

→ Contact For Your Needs

Customer Requirements:

Our Approach

Results

A carbon fiber drone frame is a lightweight structural frame made from carbon fiber plates or tubes that supports propulsion, electronics, and payload while maintaining stiffness and alignment.

Carbon fiber offers high stiffness at low weight, helping improve flight stability, vibration control, and structural efficiency.

Yes. Carbon fiber is widely used in industrial and commercial UAV platforms where structural stability and durability are required for outdoor operation.

Yes. Carbon fiber tubes are commonly used for UAV arms and booms due to their high bending and torsional stiffness at low weight.

Yes. Proper laminate design and structural layout can significantly reduce vibration transmission to cameras and sensors.

Not always. Carbon fiber propellers offer higher stiffness, but suitability depends on RPM, balance requirements, impact risk, and safety considerations.

Yes. Carbon fiber UAV components can be customized in geometry, laminate structure, thickness, and machining features based on project requirements.

Application type, drawings or dimensions, target performance requirements, quantities, and surface or finishing needs are typically required

We provide a complete portfolio of composite products for UAV & Drone applications: