Pourquoi les clients nous choisissent :

- Fabricant-Contrôle direct

- Soutien à l'ingénierie

- Une qualité constante

- Délai de livraison fiable

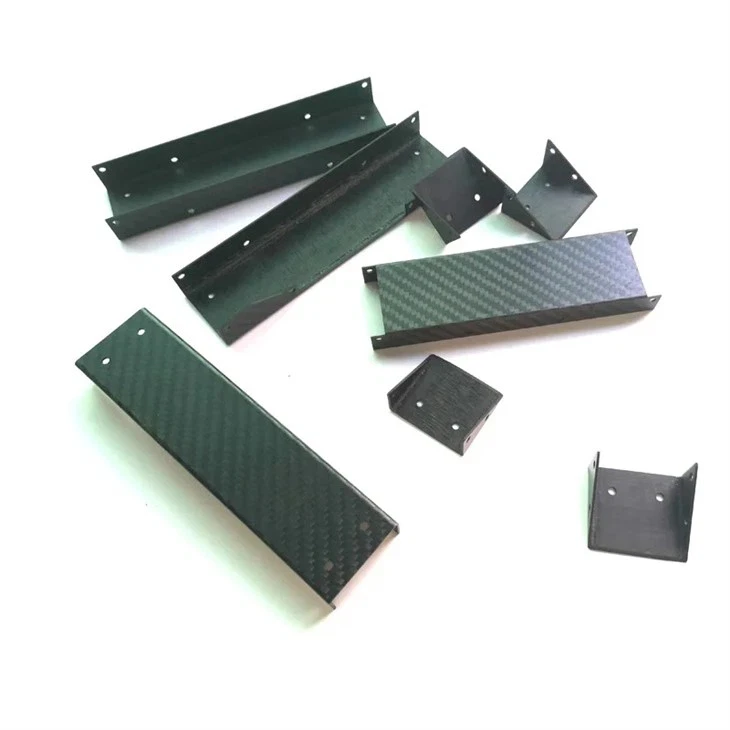

Carbon fiber brackets are structural composite mounting components engineered to support, connect, and reinforce assemblies while minimizing weight. Commonly supplied as L brackets, angle brackets, and custom geometries, these components are designed for applications where stiffness, dimensional stability, and corrosion resistance are critical.

Unlike flat carbon fiber sheets or decorative composite parts, carbon fiber brackets are load-bearing structural elements. Their geometry allows loads to be transferred efficiently through the bracket body and fastener locations, helping reduce bending, deflection, and stress concentration at joints.

The structural performance of carbon fiber brackets is primarily controlled through fiber orientation, laminate thickness, and localized reinforcement, particularly around holes, edges, and mounting interfaces. By tailoring the laminate design to the expected load direction, brackets can achieve high stiffness and fatigue resistance without unnecessary material buildup.

For industrial and OEM use, carbon fiber brackets are typically produced using epoxy-based composite systems to ensure reliable mechanical properties and long-term durability. When properly engineered, they offer superior resistance to corrosion, vibration, and cyclic loading compared with traditional metal brackets, especially in weight-sensitive structures.

Consistent performance across production batches depends on controlled material selection, layup accuracy, and curing stability. These factors play a key role in maintaining repeatable strength, dimensional accuracy, and surface quality required for scalable OEM assembly.

Material-level performance data and engineering considerations for carbon fiber are detailed in our Carbon Fiber Material Guide.

We supply a range of carbon fiber brackets engineered for structural mounting and OEM assemblies.

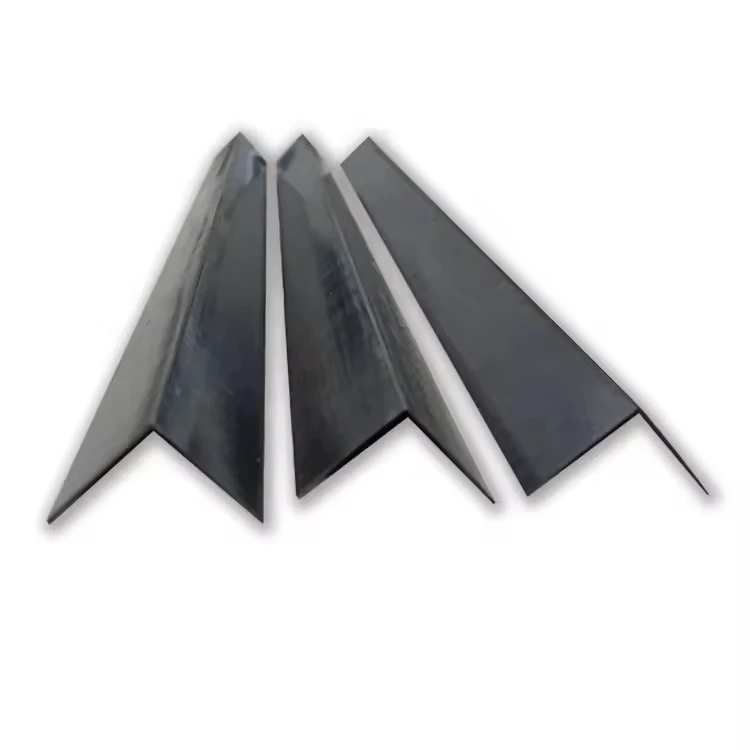

Carbon fiber L brackets are 90-degree structural connectors used for corner joints and mounting interfaces in lightweight assemblies. By optimizing fiber orientation and laminate thickness, they provide high stiffness and dimensional stability with minimal added weight.

Carbon fiber angle brackets are designed for mounting scenarios where loads transfer across an angled interface. Their geometry and laminate structure resist bending and vibration, making them suitable for dynamic and industrial assemblies.

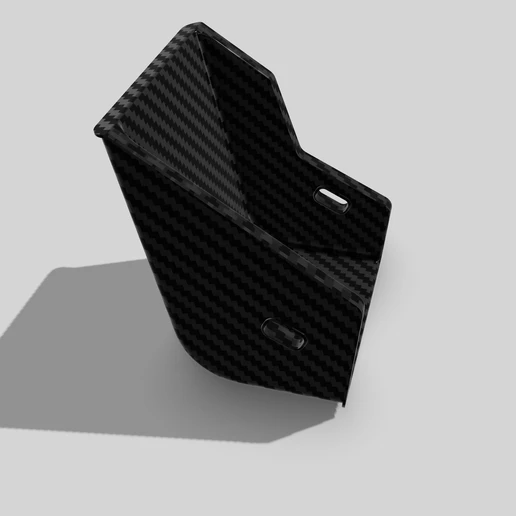

Custom carbon fiber brackets are developed when standard L or angle designs cannot meet specific structural or space requirements. Based on customer drawings, laminate architecture and reinforcement are tailored to match real load paths in OEM assemblies.

Carbon fiber brackets can be manufactured using different processes depending on geometry complexity, load requirements, and production volume.

CNC machining produces carbon fiber brackets from flat laminates and is ideal for prototypes and low-to-medium volumes. It offers high dimensional accuracy, precise hole placement, and fast iteration based on customer drawings.

Molded carbon fiber brackets are manufactured with dedicated tooling to achieve stable geometry and repeatable quality. This method is suited for higher volumes or complex shapes requiring consistent thickness and long-term structural reliability.

Bonded or hybrid assemblies are used for larger or structurally complex brackets. By integrating multiple composite parts or inserts, this approach improves load transfer, joint strength, and overall durability.

Carbon fiber brackets are supplied based on application requirements rather than fixed catalog sizes.

| Parameter | Typical Range | Notes |

|---|---|---|

| Thickness | 1.0–12.0 mm | Defined by laminate design and stiffness targets |

| Overall size | Up to ~500 mm | Larger sizes via bonded assemblies |

| Hole diameter | 3–30 mm | Reinforced hole zones available |

| Dimensional tolerance | ±0.10–0.20 mm | Depends on geometry and laminate |

| Material system | Carbon fiber + epoxy | Stable mechanical performance |

| Surface finish | Matte / gloss / clear coat | Cosmetic or protective options |

Carbon fiber brackets are used for structural mounting and reinforcement in lightweight assemblies. They support components while reducing weight and improving corrosion and vibration resistance compared to metal brackets.

In many applications, yes. Carbon fiber brackets can achieve higher stiffness-to-weight ratios than aluminum, but performance depends on laminate design, load direction, and joint configuration.

Yes. Carbon fiber brackets are commonly produced based on customer drawings, with geometry, thickness, and reinforcement tailored to specific load and assembly requirements.

We supply carbon fiber L brackets, angle brackets, and fully custom brackets designed for OEM and industrial assemblies.

Yes. Properly designed carbon fiber brackets offer excellent vibration damping and fatigue resistance under cyclic loading conditions.

Yes. Metal inserts can be integrated for torque-critical joints or applications requiring repeated assembly and disassembly.