Por qué nos eligen nuestros clientes :

- Fabricante-Control Directo

- Apoyo técnico

- Calidad constante

- Plazos de entrega fiables

Carbon fiber tubes are hollow structural composites manufactured from high-strength carbon fiber reinforcements combined with epoxy-based resin systems. Designed for structural and load-bearing use rather than decorative purposes, carbon fiber tubes deliver an exceptional strength-to-weight ratio, high stiffness, and long-term dimensional stability across demanding industrial environments.

From a material perspective, carbon fiber tubes can be produced using unidirectional fibers for maximum axial strength, or woven and braided carbon fiber architectures to improve torsional stiffness and multidirectional load handling. The selection of fiber form and layup configuration directly influences bending performance, fatigue resistance, and structural reliability, allowing tubes to be engineered for specific mechanical requirements.

In terms of manufacturing, carbon fiber tubes are commonly produced through processes such as pultrusion, filament winding, and controlled wet layup. Pultruded carbon fiber tubes offer consistent wall thickness and repeatable mechanical properties, making them suitable for long-length and batch-stable production. When combined with qualified epoxy resin systems and controlled curing parameters, these processes ensure predictable performance and durability compared with traditional metal tubes.

For B2B and OEM applications, carbon fiber tube manufacturing focuses on process control, material traceability, and production consistency. Proper alignment between fiber architecture, resin selection, and manufacturing method enables scalable production from prototype development to medium-volume manufacturing, supporting structural components used in industrial equipment, aerospace structures, marine systems, automotive platforms, performance sports structures and advanced mechanical assemblies.

For an overview of carbon fiber material properties and engineering considerations, see our Carbon Fiber Material Guide.

Wholesale carbon fiber tubes are available in various shapes and sizes, with customizable diameters, wall thicknesses, and lengths.

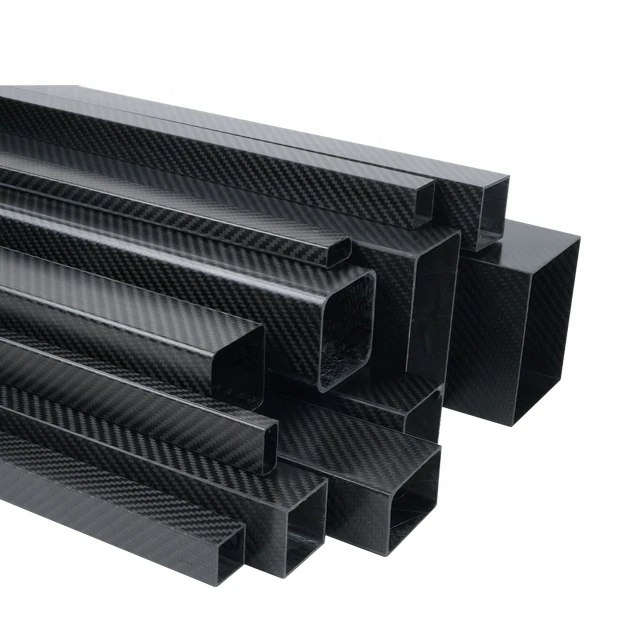

Carbon fiber square tube is a lightweight structural profile offering high stiffness and excellent anti-rotation performance. Available in common sizes such as 10mm, 20mm, 1/2 inch, and 1 inch, it is widely used in industrial frames, automation systems, sporting goods, and outdoor equipment where strength, stability, and precise geometry are required.

Carbon Fiber Tube Connectors are designed for securely joining carbon fiber tubes in lightweight structural systems. These modular carbon fiber tube connectors enable fast assembly, precise alignment, and high load stability, making them ideal for industrial frames, robotics, UAV structures, and custom composite applications.

Carbon fiber rectangular tube is a lightweight structural profile offering high stiffness and flat mounting surfaces. It is widely used in industrial frames, robotics structures, and OEM assemblies requiring dimensional stability.

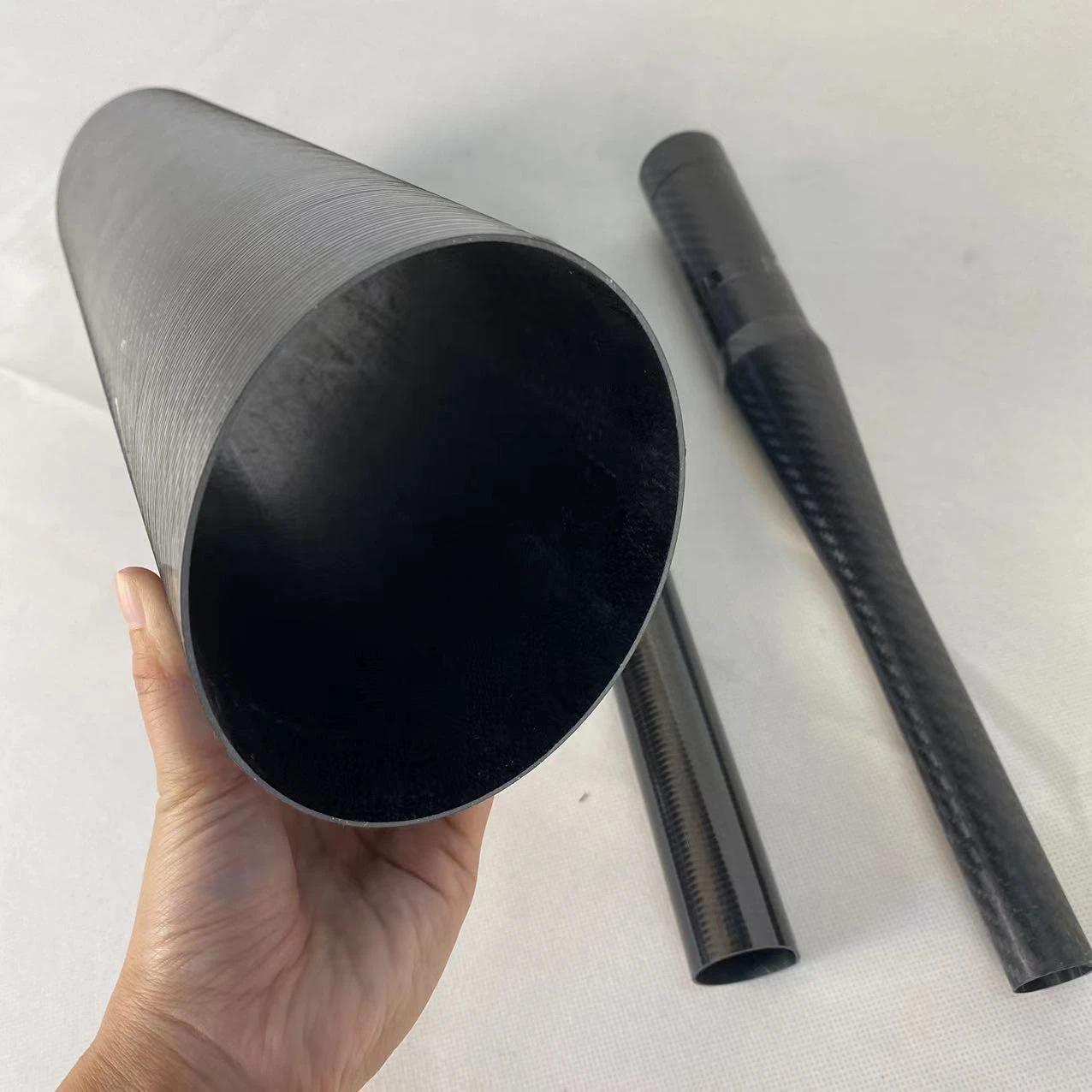

Tapered Carbon Fiber Tube features a gradually changing diameter to optimize strength distribution and reduce overall weight. Designed for structural applications such as UAV arms, robotics, and sporting equipment where stiffness and performance are critical.

Custom taper angle, length, and wall thickness available for OEM projects.

Oval carbon fiber tube is a lightweight structural solution engineered for applications requiring directional stiffness and space-efficient profiles.

Compared with round tubes, carbon fiber oval tubes provide improved bending strength along the major axis and are widely used in industrial frames, sporting goods, and OEM composite structures.

The 1 inch carbon fiber tube is a lightweight, high-strength structural tube designed for applications requiring rigidity, dimensional accuracy, and weight reduction.

Also available as a 25mm carbon fiber tube, it is widely used in industrial frames, sporting equipment, automation systems, and OEM composite assemblies.

The 2 inch carbon fiber tube is a high-strength, lightweight composite tube engineered for applications requiring larger diameters, structural rigidity, and load stability.

Also available as a 50mm carbon fiber tube, it is commonly used in industrial frameworks, automation systems, and structural OEM applications.

Roll wrapped carbon fiber tubes offer precise control of fiber layup, stiffness, and weight, supporting custom diameters and wall thicknesses.

They are well suited for OEM and structural applications requiring optimized performance and dimensional accuracy.

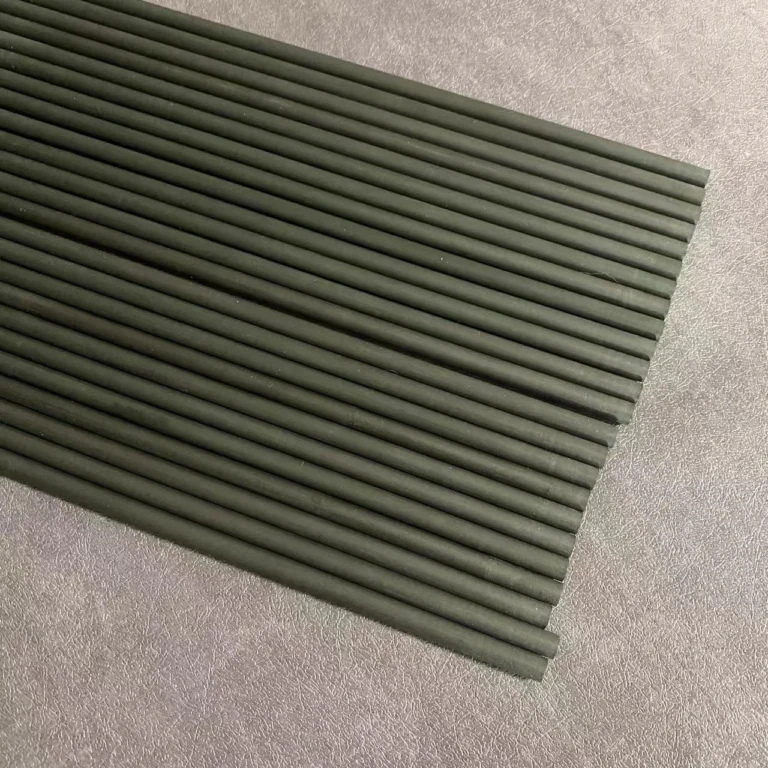

Pultruded carbon fiber tubes are produced with continuous axial fibers, delivering high tensile strength and excellent dimensional consistency.

They are ideal for standardized, high-volume applications where straightness, repeatability, and cost efficiency are critical.

Filament wound carbon fiber tubes are manufactured using continuous fibers wound at precise angles to achieve high structural efficiency.

This process delivers excellent circumferential strength and load uniformity, making the tubes suitable for pressure-bearing and high-stability structural applications.

Carbon fiber tubes are widely used across multiple industries where lightweight construction, stiffness, and durability are required.

| Parameter | Typical Options |

| Tube Shapes | Round, Square, Rectangular, Oval, Custom |

| Size Range | OD / side length: 6–500 mm |

| Wall Thickness | 0.5–20 mm (customizable) |

| Fiber Type | High-strength & high-modulus carbon fiber |

| Surface Finish | Glossy, Matte, Bonding-ready |

| Customization | Size, layup, finish per project |

Our carbon fiber sheets are manufactured through a controlled process covering material selection, fiber layup, lamination, curing, and inspection to ensure consistent mechanical performance and dimensional accuracy.

A complete range of carbon fiber tubes, covering multiple shapes, applications, and production options for standard and custom requirements.

We offer a comprehensive range of carbon fiber tubes for structural and mechanical applications, covering common diameters, wall thicknesses, and industry-standard specifications. This allows buyers to source suitable carbon fiber tubes efficiently, whether for standard designs or engineered systems.

Our product range includes carbon fiber square tube, round, rectangular, and oval profiles, each designed to meet different structural and assembly requirements. Engineers can select tube shapes based on load direction, torsional stiffness, mounting interfaces, and space constraints.

Carbon fiber tube uses include industrial frames, automation equipment, sporting structures, UAV components, and lightweight support systems. These applications benefit from high stiffness-to-weight ratio, corrosion resistance, and long-term dimensional stability.

For projects that require non-standard dimensions or performance, we provide custom carbon fiber tubes with tailored wall thickness, fiber orientation, and length. This ensures structural performance is aligned with specific mechanical loads and operating conditions.

As a carbon fiber tube manufacturer, we control tooling, production, and quality inspection in-house. This enables consistent dimensions, repeatable mechanical performance, and reliable supply for OEM and long-term production programs.

We support wholesale carbon fiber tubes for batch orders and repeat manufacturing. Our production system is designed for stable quality, predictable lead times, and long-term cooperation with industrial and OEM customers.

A Structural Decision for Performance-Driven Systems

In industrial and engineered applications, choosing between carbon fiber tubes and aluminum tubes is a structural decision that affects weight efficiency, stiffness control, durability, and long-term system performance—not simply a material preference.

While aluminum remains widely used for its availability and ease of machining, carbon fiber tubes are increasingly specified where structural optimization and performance-to-weight efficiency are critical.

Carbon fiber tubes deliver a significantly higher strength-to-weight ratio than aluminum tubes.

Required stiffness can be achieved with substantially lower mass

Aluminum tubes often rely on increased wall thickness or larger diameters to reach comparable rigidity

In weight-sensitive systems such as UAV structures, robotic arms, telescopic masts, and mobile equipment frames, carbon fiber tubes can reduce structural weight by 30–60% while maintaining or improving load performance.

Carbon fiber tubes are anisotropic materials. Through fiber orientation and laminate design, stiffness and strength can be engineered precisely along expected load paths.

Axial, bending, and torsional stiffness can be independently optimized

Particularly effective in structures with defined, directional loads

Aluminum tubes are isotropic, offering uniform properties in all directions. While this simplifies design, it often results in over-engineered structures to satisfy peak load requirements.

Carbon fiber tubes are inherently resistant to corrosion, moisture, and most industrial chemicals.

Suitable for marine, offshore, outdoor, and chemically aggressive environments

No oxidation or long-term surface degradation

Aluminum depends on oxide layers or additional surface treatments, and long-term durability in harsh environments is closely tied to coating quality and maintenance.

Aluminum tubes provide excellent thermal and electrical conductivity and are well suited for:

Heat dissipation structures

Grounding or shielding components

Carbon fiber tubes offer limited thermal conductivity and are typically selected for structural performance rather than thermal management.

Aluminum tubes are easily processed using conventional CNC methods, supporting high-speed, high-volume production.

Carbon fiber tubes require specialized manufacturing and machining processes, including:

Precision roll-wrapping or pultrusion

Controlled CNC cutting or waterjet processing

While fabrication complexity is higher, carbon fiber tubes enable lightweight, high-precision, application-specific structural solutions that are difficult to achieve with metal alone.

Aluminum offers lower initial material and processing costs

Carbon fiber tubes involve higher upfront investment

For performance-driven systems, carbon fiber tubes often deliver superior lifecycle value through weight reduction, corrosion resistance, fatigue performance, and structural efficiency—particularly where system performance outweighs raw material cost.

| Application Type | Recommended Material | Key Reason |

|---|---|---|

| UAV & Aerospace Structures | Tubos de fibra de carbono | Lightweight, high stiffness |

| Robotics & Automation Arms | Tubos de fibra de carbono | Directional load control |

| Telescopic & Mobile Masts | Tubos de fibra de carbono | Weight reduction & stability |

| General Industrial Frames | Aluminum | Cost efficiency |

| Heat Dissipation Structures | Aluminum | Thermal conductivity |

Choose carbon fiber tubes when your project prioritizes:

Structural weight reduction

High stiffness-to-mass efficiency

Corrosion resistance

Performance-driven structural design

Choose aluminum tubes when your project prioritizes:

Lower upfront cost

Thermal conductivity

Simplified machining and mass production

For OEMs and industrial buyers, working with a carbon fiber tube manufacturer enables structural optimization that aluminum tubes cannot achieve through geometry alone.

We offer a wide range of carbon fiber tube sizes, covering both standard and custom specifications.

Common outer diameters include:

• 6mm, 8mm, 10mm, 12mm, 16mm, 20mm, 25mm, 30mm

• Inch sizes such as 1/2”, 3/4”, and 1 inch carbon fiber tubes

Wall thickness and length can be customized based on structural requirements.

For non-standard sizes, custom tooling and layup options are supported for OEM and industrial applications.

Carbon fiber tubes are used as lightweight structural components in industrial equipment, automotive parts, robotics, sporting goods, and outdoor products, where high strength and low weight are required. They are commonly used for frames, arms, shafts, and support structures, and can be customized in size and layup for OEM applications.

There are several effective methods for cutting carbon fiber tubes, including diamond-blade saws, carbide tools, and CNC cutting. Using the proper cutting method helps ensure clean edges and minimal fiber damage.

A 3K carbon fiber tube is made using carbon fiber fabric where each tow contains 3,000 filaments, resulting in a fine weave appearance and balanced strength.

UD carbon is better for performance.

It provides higher strength and stiffness in the primary load direction compared to 3K woven carbon, which is mainly chosen for appearance and balanced properties.

No. Carbon fiber is stiffer and stronger in tension, while Kevlar is tougher and more impact-resistant, so each excels in different applications.

High-modulus, thin-wall carbon fiber tubes (usually 3K or UD layup) are used to make arrows, as they provide high stiffness, straightness, and consistent spine for accuracy.

Roll-wrapped carbon fiber is better.

It offers greater structural performance and design flexibility, while pultruded carbon fiber is mainly chosen for simple, constant cross-section and cost efficiency.