Por qué nos eligen nuestros clientes :

- Fabricante-Control Directo

- Apoyo técnico

- Calidad constante

- Plazos de entrega fiables

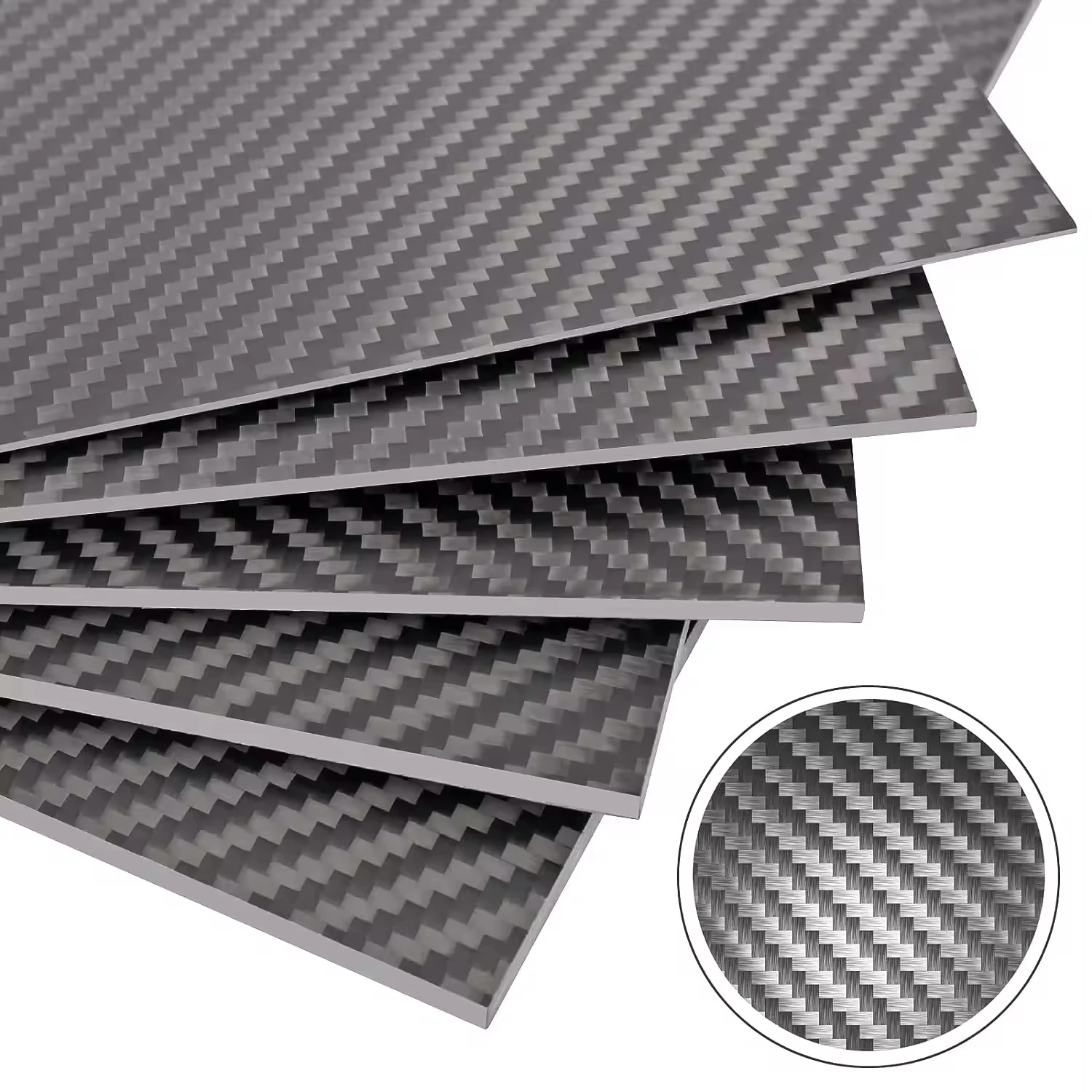

Carbon fiber sheets are flat, laminated composite materials manufactured by stacking multiple layers of carbon fiber fabric and curing them with a controlled resin system. Known for their high strength-to-weight ratio, stiffness, and dimensional stability, carbon fiber sheets are widely used in industrial, structural, and OEM applications where performance and weight reduction are critical.

Unlike decorative carbon fiber skins or veneers, carbon fiber sheets are structural materials designed to withstand mechanical loads. They can be produced using different fiber weaves and layup orientations—such as plain weave, twill weave, or quasi-isotropic configurations—to achieve specific strength and stiffness requirements. The cured laminates provide excellent machinability, making them suitable for CNC cutting, drilling, and secondary processing.

Carbon fiber sheets are commonly combined with epoxy resin systems to create high-performance composite panels. When properly designed and manufactured, these laminates offer superior fatigue resistance, corrosion resistance, and long-term durability compared to traditional materials such as steel or aluminum. As a result, they are frequently used in automotive components, industrial structures, equipment housings, and custom composite parts.

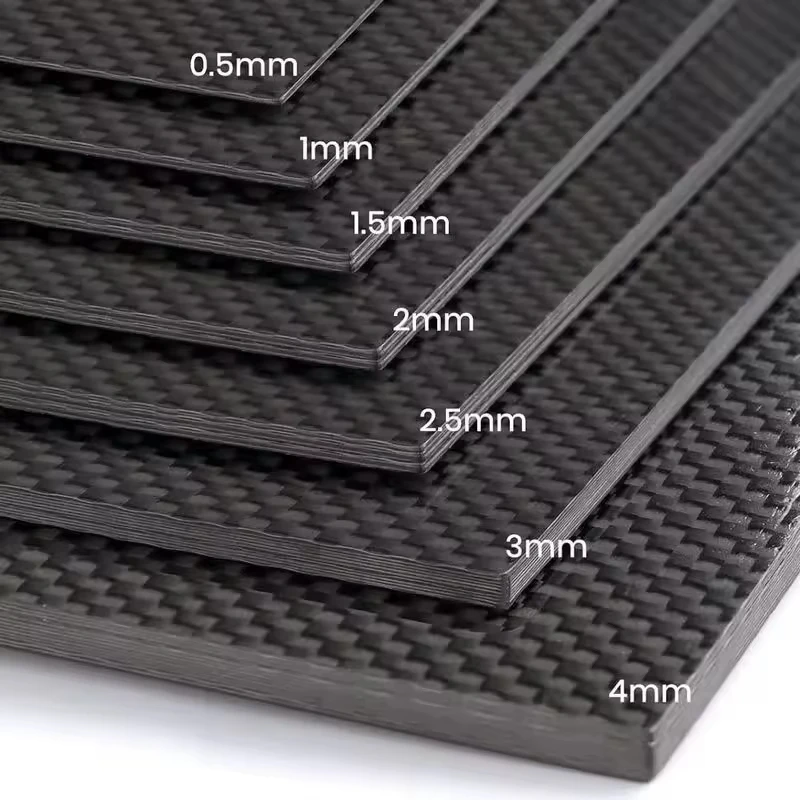

To ensure consistent performance in production environments, carbon fiber sheets should be manufactured with controlled thickness, uniform fiber distribution, and reliable curing processes. For OEM and large-volume applications, material selection, layup design, and resin compatibility play a critical role in achieving repeatable mechanical properties and surface quality.

For an overview of carbon fiber material properties and engineering considerations, see our Carbon Fiber Material Guide.

Wholesale carbon fiber sheets in various thicknesses, sizes, and finishes for industrial, OEM, and custom fabrication applications.We can meet all your needs!

Standard 4×8 carbon fiber sheets suitable for large-format cutting, fabrication, and OEM production.Standard 4×8 carbon fiber sheets suitable for large-format cutting, fabrication, and OEM production.

3mm carbon fiber sheet commonly used for CNC machining, structural panels, and industrial composite applications.

4mm carbon fiber sheets used in load-bearing panels and reinforced structural parts, providing higher rigidity and stability for industrial assemblies and repeat manufacturing applications.

Flexible sheet solutions for surface protection, finishing, and secondary bonding in OEM applications.

Includes ultra-thin carbon fiber veneers and flexible composite or film materials, designed for conformability and durability, not structural load-bearing.

Colorful carbon fiber sheets are structural composite panels that combine engineered carbon fiber reinforcement with pigmented resin systems, offering consistent mechanical performance while enabling visual differentiation for OEM, industrial, and design-driven applications.

Solid carbon fiber sheets are rigid, fully cured composite laminates designed for load-bearing applications, offering high stiffness, strength, and dimensional stability where lightweight structural performance is required.

Custom cut carbon fiber sheets are precision-machined composite panels supplied to customer-defined dimensions and tolerances, enabling direct integration into OEM assemblies and engineered structures with minimal secondary processing.

Carbon fiber sheets are used across a wide range of structural, functional, and design-driven applications where lightweight construction, dimensional stability, and consistent material performance are required.

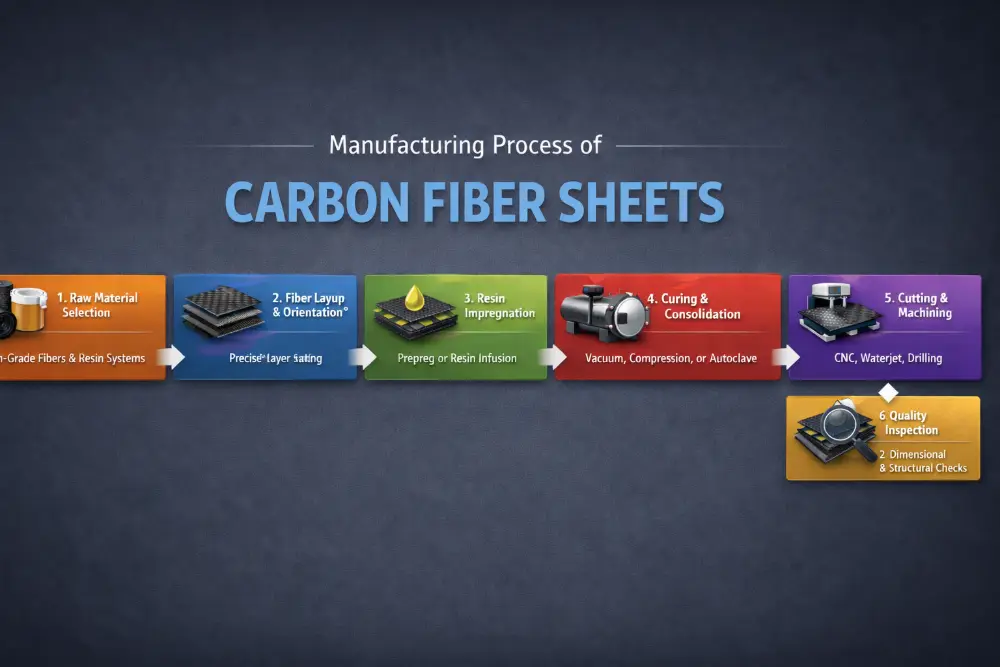

From material selection to final curing, every step of our carbon fiber sheet manufacturing process is tightly controlled to ensure consistent mechanical performance and dimensional accuracy.

High-quality carbon fiber sheets start with premium raw materials. We use high-strength and high-modulus carbon fibers, such as T700 and T800 grades, combined with carefully selected epoxy resin systems to ensure consistent structural performance and long-term reliability.

Carbon fiber sheets are produced through controlled layup and lamination, with fiber orientation and layer stacking optimized to deliver consistent strength, stiffness, and predictable structural performance.

Resin impregnation and lamination are carefully controlled to ensure uniform resin distribution and strong fiber bonding across the laminate.

Depending on the production method, this may involve prepreg lamination or controlled resin infusion, with consolidation processes applied to minimize voids and improve surface quality and final strength.

After lamination, carbon fiber sheets are cured under controlled temperature and pressure to ensure proper resin consolidation, dimensional stability, and repeatable mechanical performance.

After curing, carbon fiber sheets are cut and finished to precise tolerances, supporting CNC machining, secondary processing, and OEM assembly requirements.

Each carbon fiber sheet undergoes quality inspection to verify thickness tolerance, surface condition, and structural consistency before delivery.

This quality control process ensures reliable performance and suitability for demanding industrial applications.

A well-controlled manufacturing process ensures consistent quality, predictable performance, and reliable dimensional accuracy—critical factors for industrial and OEM carbon fiber sheet applications.

By controlling each production stage, we reduce variability across batches and deliver carbon fiber sheets that perform reliably in demanding environments.

Structural carbon fiber sheets con consistent quality, precise thickness control, and OEM-ready

Built as carbon fiber laminate sheets, engineered for load-bearing use rather than decorative surfaces.

Consistent mechanical properties make them suitable for repeatable industrial and OEM applications.

Our sheets are produced with controlled thickness ranges to ensure stable stiffness and fit.

This consistency is essential for CNC machining, assembly tolerance, and batch production.

We supply large carbon fiber sheets, including standard 4×8 panel formats.

Fewer joints improve structural integrity and production efficiency in industrial designs.

Designed for predictable machining, our sheets support clean cutting and drilling.

This reduces processing risk and improves yield in downstream manufacturing.

We provide real carbon fiber sheets, not cosmetic or substitute materials.

Material authenticity ensures dependable strength, durability, and long-term performance.

Layup options can be adjusted to match directional load and stiffness requirements.

This allows carbon fiber sheets to function as engineered materials, not generic panels.

Carbon fiber sheets and aluminum are both widely used materials in industrial and structural applications. While aluminum has long been the standard choice, carbon fiber sheets are increasingly adopted in projects where weight reduction, stiffness, and performance optimization are critical.

Below is a practical comparison to help engineers and buyers choose the right material.

One of the biggest advantages of carbon fiber sheets is their exceptional strength-to-weight ratio.

Carbon fiber sheets deliver high tensile strength while remaining extremely lightweight

Aluminum offers good strength but requires greater thickness to achieve comparable stiffness

In weight-sensitive applications such as drones, robotics, and automotive components, carbon fiber sheets can reduce overall weight by 30–60% compared to aluminum while maintaining structural integrity.

Carbon fiber sheets can be engineered with specific fiber orientations (0°, 90°, ±45°), allowing stiffness to be optimized in targeted load directions. This makes them ideal for applications with directional stress requirements.

Aluminum, on the other hand, is isotropic—its mechanical properties are the same in all directions. While this simplifies design, it limits performance optimization.

Carbon fiber sheets excel in engineered, load-specific designs, whereas aluminum is better suited for general-purpose structures.

Carbon fiber sheets are naturally resistant to corrosion, moisture, and most chemicals, making them suitable for harsh or outdoor environments.

Aluminum forms a protective oxide layer but can still corrode in marine or chemically aggressive conditions without additional surface treatment.

For long-term durability in demanding environments, carbon fiber sheets often offer superior performance.

Aluminum provides excellent thermal and electrical conductivity, making it ideal for:

Heat dissipation

Electrical grounding

Enclosures requiring thermal management

Carbon fiber sheets are electrically conductive but have lower thermal conductivity compared to aluminum. They are not typically used as heat sinks.

Aluminum is easy to machine using standard CNC processes, with high cutting speeds and low tooling costs.

Carbon fiber sheets require specialized machining techniques such as:

CNC cutting with dust control

Waterjet cutting

Diamond-coated tools

Although machining carbon fiber is more complex, it enables high-precision, lightweight custom components.

Aluminum generally has a lower material and machining cost

Carbon fiber sheets have a higher upfront cost due to raw materials and manufacturing processes

However, for performance-driven applications, carbon fiber sheets often deliver better lifecycle value through weight reduction, durability, and structural efficiency.

| Application | Better Choice | Reason |

|---|---|---|

| Drones & UAVs | Planchas de fibra de carbono | Lightweight & stiffness |

| Robotics | Planchas de fibra de carbono | Directional strength |

| Automotive panels | Planchas de fibra de carbono | Weight reduction |

| Heat sinks | Aluminum | Thermal conductivity |

| General structural frames | Aluminum | Cost efficiency |

Choose carbon fiber sheets if your project prioritizes:

Lightweight design

High stiffness and strength

Corrosion resistance

Performance-focused engineering

Choose aluminum if your project prioritizes:

Lower upfront cost

Thermal conductivity

Simple machining and mass production

Both materials have their place, but carbon fiber sheets are increasingly replacing aluminum in applications where performance outweighs material cost.

You can buy carbon fiber sheets directly from us as a manufacturer, which is ideal for OEM and industrial buyers.

Carbon fiber sheets are typically cut using bandsaws, scroll saws, jigsaws,,diamond-coated or carbide tools, waterjet, or CNC machining to achieve clean edges and minimize fiber damage.

Forged carbon fiber sheets offer isotropic strength and complex shapes, while honeycomb carbon fiber sheets provide maximum stiffness at minimal weight for large structural panels.

Carbon fiber sheets are used for lightweight structural and reinforcement applications in automotive, industrial equipment, aerospace, sporting goods, and custom composite parts where high strength and stiffness are required.

Carbon fiber sheets are relatively expensive, typically costing several times more than aluminum or fiberglass, depending on thickness, fiber grade, and manufacturing process.

Carbon fiber sheets are more expensive than traditional materials, brittle under impact, labor-intensive to manufacture, y difficult to recycle compared with metals.

Carbon fiber is stronger than aluminium by weight, offering a much higher strength-to-weight ratio, while aluminium is stronger only in terms of absolute ductility and impact tolerance.

A 4×8 carbon fiber sheet typically weighs between 6–25 kg (13–55 lb), depending mainly on its thickness and laminate structure.

3K, 12K, and 18K carbon refer to the number of carbon filaments bundled in a single tow (3,000 / 12,000 / 18,000 fibers).

3K carbon fiber is commonly used for fine-weave, high-precision carbon fiber sheets, offering better surface finish and tighter layups, while 12K and 18K carbon fiber are optimized for cost efficiency and structural thickness build-up.

12K carbon fiber is stronger in load-bearing applications.

Its larger tow size provides higher load capacity, while 3K is mainly used for finer surface appearance and balanced performance.