Por qué nos eligen nuestros clientes :

- Fabricante-Control Directo

- Apoyo técnico

- Calidad constante

- Plazos de entrega fiables

| Material | Density (g/cm³) | Tensile Strength (MPa) | Specific Strength* | Tensile Modulus (GPa) | Data Source | |

| Carbon Fiber Composite (Epoxy) | 1.5–1.8 | 600–1500 | 400–1000 | 70–230 | ASM / NASA | |

| Aluminum 6061-T6 | 2.7 | ~310 | ~115 | 69 | Aluminum Association | |

| Structural Steel (A36) | 7.85 | 400–550 | ~55 | 200 | World Steel | |

| E-Glass Composite | 1.9–2.1 | 500–900 | ~260–430 | 20–30 | Owens Corning | |

In practical design, carbon fiber strain is commonly interpreted as strain-to-failure, while carbon fiber modulus defines stiffness along the fiber direction.

Carbon fiber tensile strength indicates maximum load capacity before failure but must be evaluated together with fiber orientation and laminate design.

| Material | Fatigue Behavior | Corrosion Resistance | Reference |

| Carbon Fiber Composite | Minimal strength loss after 10⁶ cycles | Excellent | ASTM D3479 / FAA |

| Aluminum Alloys | Progressive fatigue cracking | Good | ASM |

| Structural Steel | High fatigue sensitivity | Poor–Fair | World Steel |

| Fiberglass Composite | Good fatigue resistance | Excellent | CompositesWorld |

Actual performance varies depending on alloy grade, fiber architecture, resin system, and manufacturing process. The data above represents typical engineering reference ranges used for material comparison.

Carbon fiber material is supplied in multiple product forms to meet different structural, machining, and assembly requirements.

Carbon fiber tubes are hollow structural forms designed to deliver high bending stiffness and torsional strength at low weight.

Carbon fiber sheets and plates are flat laminate materials supplied for machining, cutting, and secondary fabrication.

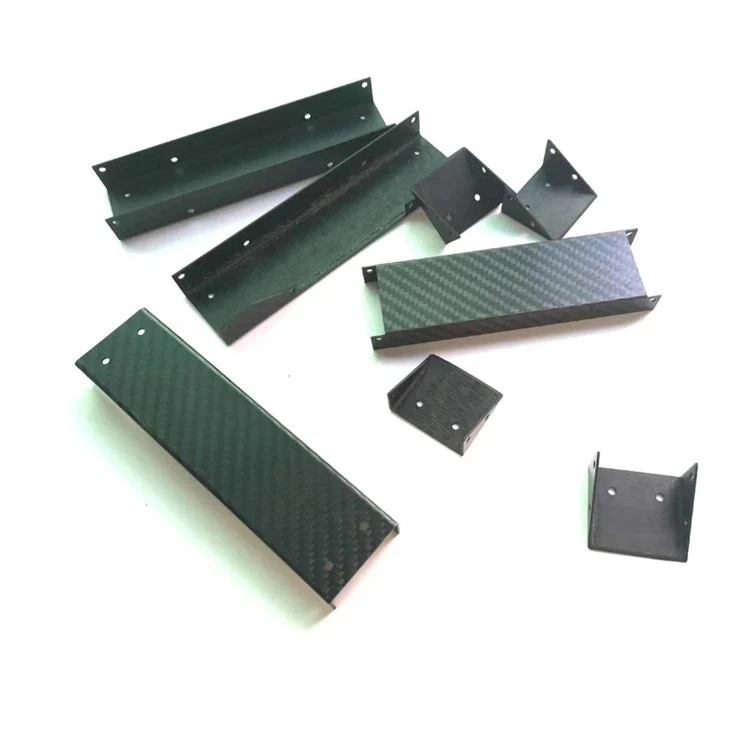

Carbon fiber can be engineered into custom structural parts and profiles through molding, layup, and machining processes.

Carbon fiber rods are solid composite profiles offering high axial stiffness and dimensional stability.

The selection of carbon fiber product form depends on load conditions, geometry, manufacturing method, and cost considerations.

While carbon fiber offers exceptional performance advantages, its effective use requires proper engineering design and an understanding of its material limitations.

Anisotropy & Load Direction

Carbon fiber composites are anisotropic materials, meaning their mechanical properties vary with fiber orientation.

Maximum strength and stiffness are achieved along the fiber direction, making laminate design and load path definition critical in structural applications.

Failure Behavior & Impact Sensitivity

Unlike metals, carbon fiber does not plastically deform before failure.

Overloading or impact can lead to sudden fracture or internal delamination, which may not be visible on the surface but can significantly reduce structural integrity.

Manufacturing & Cost Considerations

Carbon fiber components require specialized manufacturing processes, tooling, and quality control.

Material cost, processing complexity, and production volume must be evaluated early to balance performance benefits with economic feasibility.

Environmental & Thermal Limits

The performance of carbon fiber composites is strongly influenced by the selected resin system.

Service temperature range, UV resistance, and moisture durability depend on resin chemistry and surface protection rather than the carbon fibers themselves.

Carbon arrow shafts, pool cues, hockey shafts, lacrosse shafts and sporting CFRP components

OEM carbon fiber and composite products manufactured for stiffness, weight reduction, and performance-driven sports equipment applications.

Cleaning poles, inspection poles, field tools and telescoping composite components

Lightweight and durable carbon fiber products optimized for portability, reach, and operational reliability in outdoor tools.

Drone frames, arms, landing gear and lightweight structural components

High-strength carbon fiber structures engineered for optimized strength-to-weight performance in UAV and drone applications.

Robot arms, booms, structural links and custom CFRP components

Precision-manufactured composite parts designed for rigidity, dimensional stability, and dynamic performance in robotic systems.

Structural reinforcements, interior trim parts and custom CFRP components

Carbon fiber solutions focused on weight reduction, functional integration, and durability for automotive and mobility applications.

Cleaning poles, inspection poles, field tools and telescoping composite components

Lightweight and durable carbon fiber products optimized for portability, reach, and operational reliability in outdoor tools.

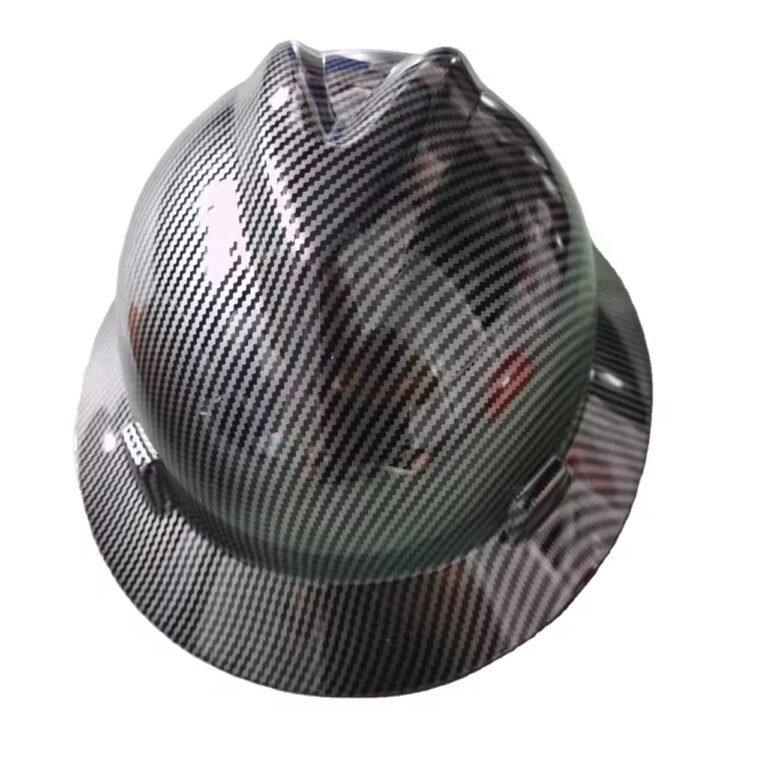

Protective inserts, helms,reinforcement panels and impact-resistant composite components

Carbon fiber and composite parts engineered for protection, structural integrity, and safety-critical applications.

The comparison below is based on public engineering handbooks, aerospace material databases, and industry standards, commonly referenced during material selection.

| Material | Density (g/cm³) | Reference |

|---|---|---|

| Carbon Fiber Composite (epoxy) | 1.5 – 1.8 | ASM International |

| Aluminum 6061-T6 | 2.70 | The Aluminum Association |

Engineering implication:

Carbon fiber composites are typically 30–45% lighter than aluminum for equivalent structural volume, making them preferable in weight-critical designs.

| Material | Tensile Strength (MPa) | Density (g/cm³) | Specific Strength* |

|---|---|---|---|

| Carbon Fiber Composite | 600 – 1500 | 1.5 – 1.8 | 400 – 1000 |

| Aluminum 6061-T6 | ~310 | 2.70 | ~115 |

*Specific Strength = Tensile Strength / Density (relative comparison)

Data sources:

ASM Handbook, Volume 21 – Composites

Aluminum Association – 6061-T6 Datasheet

Engineering implication:

Carbon fiber delivers 3–8× higher specific strength than aluminum, which is why it replaces aluminum in aerospace, UAV, and high-performance structures.

| Material | Tensile Modulus (GPa) | Reference |

|---|---|---|

| Carbon Fiber Composite | 70 – 230 (fiber-direction) | NASA |

| Aluminum 6061-T6 | ~69 | Aluminum Association |

Engineering implication:

Aluminum provides isotropic stiffness (same in all directions).

Carbon fiber stiffness is direction-dependent, allowing engineers to place stiffness only where needed—resulting in lighter structures.

| Performance Aspect | Carbon Fiber | Aluminum | Reference |

|---|---|---|---|

| Fatigue Behavior | Minimal degradation after 10⁶ cycles | Progressive crack growth | ASTM D3479 / ASM |

| Corrosion Resistance | Immune to corrosion | Susceptible without protection | NASA / ASM |

| Typical Service Life | 15–25+ years | Design-dependent | FAA / ASM |

Engineering implication:

Carbon fiber performs exceptionally well in cyclic loading environments, while aluminum requires careful fatigue and corrosion management.

| Parameter | Carbon Fiber Composite | Aluminum | Reference |

|---|---|---|---|

| Coefficient of Thermal Expansion | −0.1 to 1.0 µm/m·K | ~23 µm/m·K | NASA |

| Continuous Service Temperature | Resin-dependent (120–250 °C) | >200 °C | ASM |

Engineering implication:

Carbon fiber offers excellent dimensional stability under temperature change, while aluminum expands significantly with heat.

| Factor | Carbon Fiber | Aluminum |

|---|---|---|

| Material Cost | Higher | Lower |

| Manufacturing | Composite layup, molding, curing | Machining, extrusion, forming |

| Design Flexibility | High (custom layups) | Moderate |

| Best Use Case | Weight-critical, high performance | Cost-sensitive, high volume |

Carbon fiber is typically selected over aluminum when:

Weight reduction is critical

High specific strength or stiffness is required

Fatigue resistance and corrosion immunity are important

Custom structural optimization justifies higher material cost

Aluminum remains advantageous where:

Cost sensitivity dominates

Isotropic properties are preferred

High-volume, simple geometries are required

ASM Handbook, Volume 21 – Composites

NASA Materials and Processes Technical Information System (MAPTIS)

ASTM D3039 / ASTM D3479

The Aluminum Association – Aluminum 6061-T6 Datasheets

FAA Advisory Circular AC 20-107B

Yes, carbon fiber has a significantly higher strength-to-weight ratio than steel.

While steel may offer higher absolute strength in bulk form, carbon fiber provides comparable or higher tensile strength at a much lower weight, making it more efficient in weight-sensitive structural applications.

In terms of specific strength and stiffness, carbon fiber outperforms aluminum.

Carbon fiber composites can achieve several times the strength-to-weight ratio of aluminum alloys, which is why they are often selected in aerospace, UAV, and high-performance structural designs.

Carbon fiber does not plastically deform like metals and is considered a brittle material in failure behavior.

When overloaded, it may fail suddenly rather than bending, which is why proper laminate design, safety factors, and impact considerations are critical in engineering applications.

Carbon fiber strain typically refers to strain-to-failure, which indicates how much deformation the material can withstand before fracture.

For standard carbon fiber composites, strain-to-failure values generally range from approximately 1.3% to 2.1%, depending on fiber grade, resin system, and laminate architecture.

Carbon fiber composites offer excellent fatigue resistance and do not corrode like metals.

When properly designed and protected from excessive impact or environmental exposure, carbon fiber components can achieve service lives of 15–25 years or more in structural applications.

Carbon fibers themselves are thermally stable, but the resin system determines heat and moisture resistance.

Continuous service temperature and environmental durability depend on resin selection, surface protection, and operating conditions rather than the carbon fibers alone.

Carbon fiber may not be ideal for cost-sensitive, high-volume designs, applications requiring ductile deformation, or environments involving severe impact without inspection capability.

In such cases, metals or alternative composites may provide a more suitable balance of performance and cost.