Warum Kunden uns wählen :

- Hersteller-Direktsteuerung

- Technische Unterstützung

- Gleichbleibende Qualität

- Verlässliche Vorlaufzeit

We specialize in custom carbon fiber parts and carbon fiber fabrication, providing end-to-end OEM and ODM manufacturing services for industrial and commercial applications.

From custom cut carbon fiber sheets to fully engineered structural components, we support projects from early-stage prototyping to stable mass production.

Whether you require precision cutting, composite fabrication, or long-term OEM carbon fiber solutions, our engineering-driven process ensures reliable quality, consistent performance, and predictable lead times.

Capabilities at a glance:

Fabrication · CNC & Laser Cutting · Composite Manufacturing · OEM / ODM Support

To support a wide range of custom carbon fiber fabrication projects, we offer flexible material and structural options.

All materials and configurations can be customized according to drawings or confirmed specifications.

| Category | Options Available | Description | Related Products |

|---|---|---|---|

| Fiber Types | Carbon Fiber | High strength-to-weight ratio, widely used for structural and functional parts | Kohlefaser-Stäbe / Carbon Fiber Sheets / Carbon Fiber Plates |

| Carbon Kevlar (Carbon–Aramid Hybrid) | Improved impact resistance and durability | Carbon-Kevlar-Rohre | |

| Fiberglass | Cost-effective composite option | Fiberglas-Rohre & Rods | |

| Resin Systems | Epoxy Resin | Excellent mechanical properties and dimensional stability | Carbonfaser-Platten |

| Weave Styles | Twill Weave | Balanced strength and premium surface appearance | Kohlefaser-Paneele |

| Plain Weave | Uniform strength and stable geometry | Kohlefaser-Platten | |

| UD (Unidirectional) | Strength optimized in a specific load direction | Kohlenstofffaser-Rohre | |

| Laminate Thickness | Custom thickness | Defined by layer count and application requirements | Carbon Fiber Sheets / Plates |

| Layer Structure | Single-layer to multi-layer | Custom ply orientation and stacking sequence | Komposit-Stäbe |

| Core Options | Foam Core | Lightweight sandwich structures | Kohlefaser-Paneele |

| Honeycomb Core | High stiffness-to-weight ratio | Kohlefaser-Paneele | |

| Oberflächenbehandlung | Gloss / Matte | Cosmetic and visible carbon fiber parts | Geschmiedete Kohlefaserteile |

| Raw Weave | Functional parts with natural weave | Kohlefaser-Streifen | |

| Paint-Ready | Secondary coating or painting | Kohlefaser-Halterungen | |

| Special Structures | Forged Carbon Fiber | Complex geometries and distinctive appearance | Geschmiedete Kohlefaserteile |

| Channels & Brackets | Mounting and structural profiles | Kohlefaser-Kanäle / Brackets |

We provide flexible custom carbon fiber fabrication services covering a wide range of part types and production volumes.

All components are manufactured according to customer drawings or confirmed specifications, supporting both prototype development and mass production programs.

Our customization scope includes:

This approach allows customers to consolidate fabrication, cutting, and finishing with one qualified manufacturing partner.

| Part Type | Typical Process | Best For | Notes |

|---|---|---|---|

| Custom Carbon Fiber Parts | Prepreg layup, CNC machining | Structural & functional components | Designed per drawing, supports inserts and assemblies |

| Custom Cut Carbon Fiber Sheets | CNC / Laser / Waterjet cutting | Flat panels, covers, enclosures | Tight tolerances, clean edges, fast lead time |

| Custom Carbon Fiber Tubes | Filament winding / layup + machining | Frames, supports, load-bearing structures | Round, square, tapered, or custom profiles |

| Carbon Fiber Plates & Panels | Lamination + precision cutting | Equipment panels, mounting surfaces | Thickness and layup fully customizable |

| Carbon Fiber Sandwich Panels | Composite layup + core bonding | Lightweight, high-stiffness applications | Foam or honeycomb core options available |

| Prototype & Small Batch Parts | Flexible fabrication processes | Product validation and testing | Low MOQ, engineering feedback included |

| Mass Production Components | Standardized fabrication workflow | Stable supply programs | Consistent quality and repeatability |

Carbonpfeilschäfte, Billardqueues, Hockeyschäfte, Lacrosse-Schäfte und CFK-Sportkomponenten

OEM-Kohlefaser- und Verbundwerkstoffprodukte, die für Steifigkeit, Gewichtsreduzierung und leistungsorientierte Sportgeräteanwendungen hergestellt werden.

Reinigungsstangen, Inspektionsstangen, Feldwerkzeuge und teleskopierbare Verbundteile

Leichte und langlebige Kohlefaserprodukte, die für Tragbarkeit, Reichweite und Betriebssicherheit von Outdoor-Werkzeugen optimiert sind.

Drohnenrahmen, Arme, Fahrwerk und leichte Strukturkomponenten

Hochfeste Kohlefaserstrukturen, die für ein optimales Festigkeits-Gewichts-Verhältnis bei UAV- und Drohnenanwendungen entwickelt wurden.

Roboterarme, Ausleger, strukturelle Verbindungen und kundenspezifische CFK-Komponenten

Präzisionsgefertigte Verbundwerkstoffteile, die für Steifigkeit, Dimensionsstabilität und dynamische Leistung in Robotersystemen ausgelegt sind.

Strukturelle Verstärkungen, Innenverkleidungsteile und kundenspezifische CFK-Komponenten

Kohlefaserlösungen mit Schwerpunkt auf Gewichtsreduzierung, Funktionsintegration und Langlebigkeit für Automobil- und Mobilitätsanwendungen.

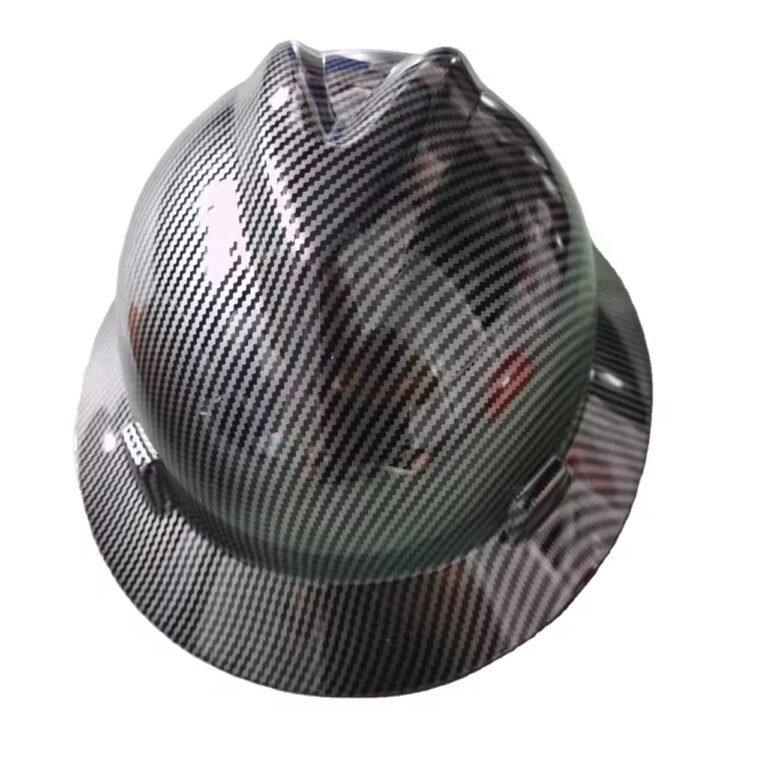

Schutzeinlagen, Helme, Verstärkungsplatten und stoßfeste Verbundwerkstoffteile

Kohlefaser- und Verbundstoffteile, die für Schutz, strukturelle Integrität und sicherheitskritische Anwendungen entwickelt wurden.

Reinigungsstangen, Inspektionsstangen, Feldwerkzeuge und teleskopierbare Verbundteile

Leichte und langlebige Kohlefaserprodukte, die für Tragbarkeit, Reichweite und Betriebssicherheit von Outdoor-Werkzeugen optimiert sind.

Our manufacturing capabilities cover the full scope of carbon fiber fabrication, cutting, machining, and composite processing, allowing us to support both prototype development and long-term production programs.

By integrating cutting, machining, and composite fabrication under one roof, we ensure better dimensional control, consistent quality, and shorter lead times for custom carbon fiber parts.

We provide multiple cutting technologies to support custom cut carbon fiber components with different thicknesses, geometries, and performance requirements.

CNC Cutting (Computer Numerical Control Cutting)

Ideal for high-precision cutting of carbon fiber sheets, plates, and panels with tight dimensional control.

Laser Cutting (Laser Cutting Service)

Suitable for complex profiles and fine features, widely used in OEM carbon fiber laser cutting service projects requiring clean edges and repeatability.

Waterjet Cutting (Waterjet Cutting)

Used for thicker laminates and applications where thermal impact must be minimized.

Tolerance Control:

Cutting tolerances are defined according to customer drawings and application needs.

Typical achievable tolerance: ±0.1 mm, depending on material thickness, process, and geometry.

For components that require assembly, fastening, or cosmetic requirements, we offer comprehensive carbon fiber machining and finishing services.

CNC Machining (Computer Numerical Control Machining) for precision features

Drilling, countersinking, slotting, and edge profiling

Installation of threaded inserts and metal fasteners

Secondary machining after laminate fabrication

Surface Finishing Options:

Gloss finish

Matte finish

Raw weave appearance

Paint-ready surface preparation

These processes ensure that custom carbon fiber parts are ready for direct integration into customer assemblies.

Beyond cutting and machining, we operate as a carbon fiber fabrication manufacturer, capable of producing structural composite components.

Prepreg Layup (Pre-impregnated Carbon Fiber Layup)

Enables precise fiber orientation and consistent resin content for high-performance parts.

Vacuum Bagging (Vacuum Bagging Process)

Improves laminate consolidation and surface quality.

Oven Curing

Controlled curing to achieve stable mechanical properties.

Compression Molding (Compression Molding)

Suitable for repeatable production parts with consistent geometry.

Filament Winding (Filament Winding)

Used for manufacturing custom carbon fiber tubes and structural profiles, offering excellent strength-to-weight performance.

Fabrication processes are selected based on structural requirements, part complexity, and production volume.

We provide structured custom CFRP manufacturing services, supporting customers from initial concept validation to long-term mass production.

Customers share project requirements, drawings, or samples for initial evaluation.

This step helps us understand application needs, performance targets, and expected quantities.

Technical files or physical samples are submitted for detailed review.

Accepted formats include STEP, STP, IGES, DWG, and PDF.

Our engineering team conducts a DFM (Design for Manufacturability) review, evaluating material selection, laminate structure, tolerances, and fabrication feasibility.

Optimization suggestions may be provided to balance performance, cost, and production efficiency.

Based on the DFM outcome, we define the fabrication process and issue a detailed quotation covering:

Recommended materials and manufacturing methods

Unit pricing based on order quantity

MOQ (Minimum Order Quantity)

Estimated lead time for prototypes and mass production

Prototype parts are manufactured for functional testing, fit verification, or visual evaluation.

This stage validates both design intent and manufacturing process.

After prototype approval, production parameters, quality standards, and batch planning are finalized to ensure repeatability in mass production.

Manufacturing is carried out under controlled and repeatable conditions, ensuring consistency in material quality, dimensions, and surface finish across batches.

This structured OEM/ODM workflow ensures transparency, engineering control, and reliable execution throughout the entire carbon fiber fabrication process.

Quality control is integrated into every stage of our custom carbon fiber fabrication process to ensure dimensional accuracy, surface consistency, and batch-to-batch reliability.

Dimensional Inspection

Dimensions and tolerances are inspected according to approved drawings and specifications, ensuring proper fit and assembly compatibility.

Appearance Inspection

Visual checks are performed to verify surface finish, weave alignment, edge quality, and cosmetic requirements for visible carbon fiber parts.

Material Traceability

Raw materials and laminate batches can be traced and documented when required, supporting OEM projects and repeat production programs.

Export Packaging

Parts are packed using export-grade packaging methods to prevent damage during international transportation.

Below are selected examples demonstrating how we support customers with custom carbon fiber fabrication and OEM solutions.

Challenge:

The customer required lightweight yet rigid carbon fiber panels for an industrial equipment enclosure, with tight dimensional tolerances and clean edges for direct assembly.

Solution:

We selected laminated carbon fiber sheets and applied CNC cutting combined with secondary edge finishing to achieve precise dimensions and smooth edges.

Result:

The final panels met all dimensional requirements, reduced overall enclosure weight, and were delivered on schedule for pilot production.

Challenge:

A customer needed custom carbon fiber tubes for a structural frame, requiring high stiffness, consistent wall thickness, and repeatable geometry.

Solution:

Filament winding and controlled curing were used to manufacture custom tube profiles, followed by CNC machining for interface features.

Result:

The tubes provided excellent strength-to-weight performance and dimensional consistency, supporting stable mass production.

Yes. Custom carbon fiber parts can be manufactured using 3K or 12K carbon fiber, depending on structural and appearance requirements.

3K is commonly selected for finer surface appearance, while 12K is often used where thicker tows or different stiffness characteristics are acceptable.

Yes. T700 carbon fiber is commonly used in custom carbon fiber manufacturing for applications requiring a balance between strength, stiffness, and cost.

The final fiber grade is selected based on mechanical requirements and production considerations.

3K refers to the tow size (number of filaments per bundle), while T700 refers to the carbon fiber grade.

A custom carbon fiber part can use T700 fiber in either 3K or larger tow formats depending on design and appearance needs.

Yes. Custom carbon fiber parts can be supplied in black, colored, or tinted finishes, depending on resin systems, surface coatings, or cosmetic layers.

Color selection is typically driven by application requirements rather than structural performance.

To start a quotation, suppliers typically need:

This information helps determine the most cost-efficient and reliable production solution.

Yes. Custom cut carbon fiber sheets can be manufactured using 3K carbon fiber fabric, especially when surface appearance is important.

Laminate thickness and internal layup can be adjusted independently of the outer fabric style.

Both woven carbon fiber und UD carbon fiber are used in custom carbon fiber parts.

Woven fabrics are often chosen for balanced properties and appearance, while UD laminates are selected for directional strength and stiffness.

Fiber appearance (such as 3K twill or plain weave) has limited impact on strength compared to laminate design and fiber orientation.

Structural performance is primarily controlled by layup strategy rather than cosmetic fabric choice.

Ja. Custom carbon fiber tubes can be supplied with either glossy or matte finishes, depending on surface coating and post-processing methods.

Finish selection does not significantly affect mechanical performance.

Yes. Custom carbon fiber parts can be supplied with controlled weave patterns, matte or gloss finishes, painted surfaces, or protective coatings, making them suitable for consumer-facing and branded products.

Yes. Custom carbon fiber parts can incorporate hybrid laminates, combining carbon fiber with fiberglass or aramid layers.

Hybrid construction is often used to balance stiffness, impact resistance, and cost.

Compared with aluminum or plastic, custom carbon fiber parts offer:

This makes carbon fiber a preferred choice for performance-focused or brand-visible components.

Phone Number

Address

Weihai Stadt , Provinz ShanDong 264200