Warum Kunden uns wählen :

- Hersteller-Direktsteuerung

- Technische Unterstützung

- Gleichbleibende Qualität

- Verlässliche Vorlaufzeit

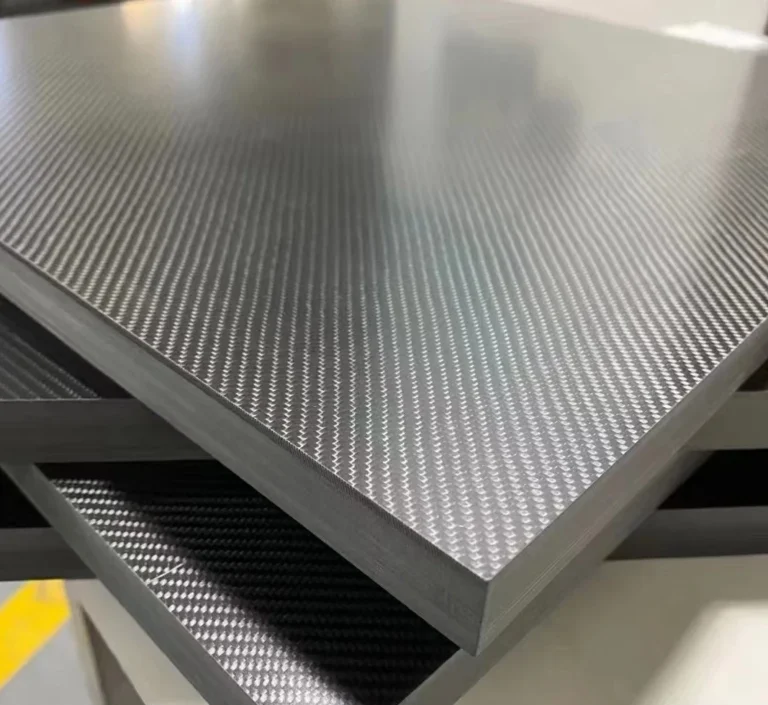

Carbon fiber plates are precision-made composite products used where rigid support, low weight, and structural stability are required. Rather than acting as basic raw materials, these plates are supplied as finished or semi-finished components that can be directly applied or further machined into functional parts.

By adjusting laminate structure, thickness, and fiber orientation, carbon fiber plates can be engineered to meet specific stiffness, strength, and impact requirements. Rigid carbon fiber plates are commonly used for structural reinforcement, while forged carbon fiber plates provide more uniform strength distribution for complex or impact-sensitive applications.

From a manufacturing standpoint, carbon fiber plates are produced under controlled processes to ensure dimensional accuracy and repeatable performance. They can be CNC machined into build plates, keyboard plates, skid plates, wing end plates, footwear plates, and other plate-based products without compromising structural integrity. This makes carbon fiber plates suitable for OEM and custom production across automotive, industrial, electronics, and performance-driven applications.

Einen Überblick über die Materialeigenschaften von Kohlenstofffasern und technische Überlegungen finden Sie in unserem Leitfaden für Kohlefaserwerkstoffe.

OEM-grade carbon fiber plates for wholesale supply, manufactured into custom plate-based products for OEM applications.

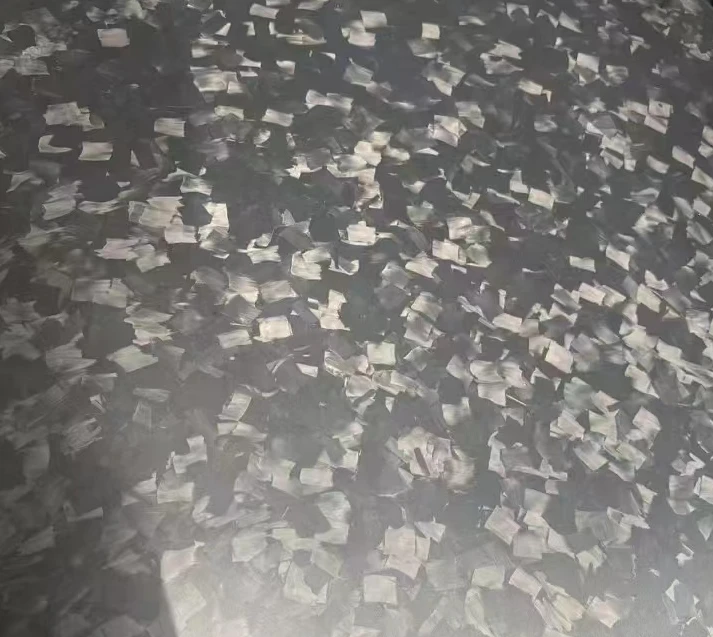

Forged carbon fiber plates offer more uniform strength distribution and improved impact resistance, making them suitable for complex geometries and OEM plate-based components.

Carbon fiber wing end plates deliver lightweight structural support and stiffness control for aerodynamic and performance-focused applications.

Carbon fiber keyboard plates provide consistent stiffness and precise machining tolerance, supporting stable assembly in custom hardware and electronics applications.

Carbon fiber build plates provide high stiffness and dimensional stability for industrial and mechanical systems, supporting precision assemblies and repeatable production environments.

Carbon fiber skid plates are manufactured for impact protection and weight reduction, commonly used in automotive and mechanical applications requiring durable plate structures.

Carbon fiber foot plates are engineered for controlled flex and structural support, widely applied in performance footwear and sports-related plate components.

Carbon fiber license plate frames are produced as lightweight, rigid plate-based components for automotive applications, supporting OEM customization and batch supply.

Carbon fiber plates are widely used in plate-based components across automotive, industrial, electronics, and performance applications.

| Parameter | Typische Optionen |

| Plate Types | Solid, Rigid, Forged, Custom |

| Thickness Range | 0,5-20 mm (anpassbar) |

| Plate Size | Custom cut to project requirements |

| Fiber Architecture | Unidirectional, Woven, Multi-axial |

| Faser-Typ | Hochfeste und hochmodulige Kohlefaser |

| Resin System | Epoxy (standard), high-temperature options available |

| Oberflächenbehandlung | Glossy, Matte, Textured, Bonding-ready |

| Machining Options | CNC cutting, drilling, edge finishing |

| Personalisierung | Thickness, layup, size, finish per OEM project |

Carbon fiber plates are manufactured through controlled composite processes that ensure consistent quality and structural performance. From fiber selection and laminate design to curing and precision machining, each step is optimized to meet OEM and custom production requirements, supporting repeatable manufacturing and reliable plate-based components.

Our carbon fiber plates are engineered and manufactured to meet the technical, quality, and consistency requirements of OEM and custom production.

Our carbon fiber plates are produced under controlled processes to ensure consistent quality, structural reliability, and suitability for OEM supply.

We tailor fiber layup, orientation, and plate thickness to meet specific stiffness, strength, and application requirements.

In-house machining enables accurate cutting, drilling, and finishing for plate-based components and custom designs.

Defined material standards and process controls support repeat orders and long-term production programs.

Carbon fiber plates are rigid composite panels made from layered carbon fiber reinforced with resin.

Fiber plates offer high strength, low weight, and excellent structural stability for performance-critical applications.

Carbon fiber plates are used in applications that require lightweight structural support and high stiffness.

They are widely applied in aerospace components, robotics structures, automotive parts, industrial equipment, sports technology, and other performance-driven designs where weight reduction and rigidity are critical.

Carbon fiber plates are extremely strong relative to their weight.

They offer a much higher strength-to-weight ratio than metals like aluminum, and their strength can be engineered through fiber orientation and laminate design to handle specific load directions and stresses.

Carbon fiber plates are made from carbon fiber fabrics or prepregs bonded with a resin matrix.

Carbon fiber plates are better than aluminum when lightweight, high stiffness, and performance optimization are required.