Carbon Fiber Explained: Strength, Weight, Durability, and How to Choose the Right Solution

Carbon fiber is widely recognized as one of the most important structural materials in modern manufacturing. It is used across sports equipment, drones, robotics, automotive components, industrial tools, and other products where weight reduction, mechanical strength, and long-term reliability directly influence performance.

Despite its growing adoption, carbon fiber is often misunderstood. Some descriptions reduce it to a “super material,” while others rely on highly technical explanations that offer little practical value for real-world product decisions.

In practice, carbon fiber is best understood through how it performs, how it compares to alternative materials, and how it behaves when applied in actual products.

What Is Carbon Fiber

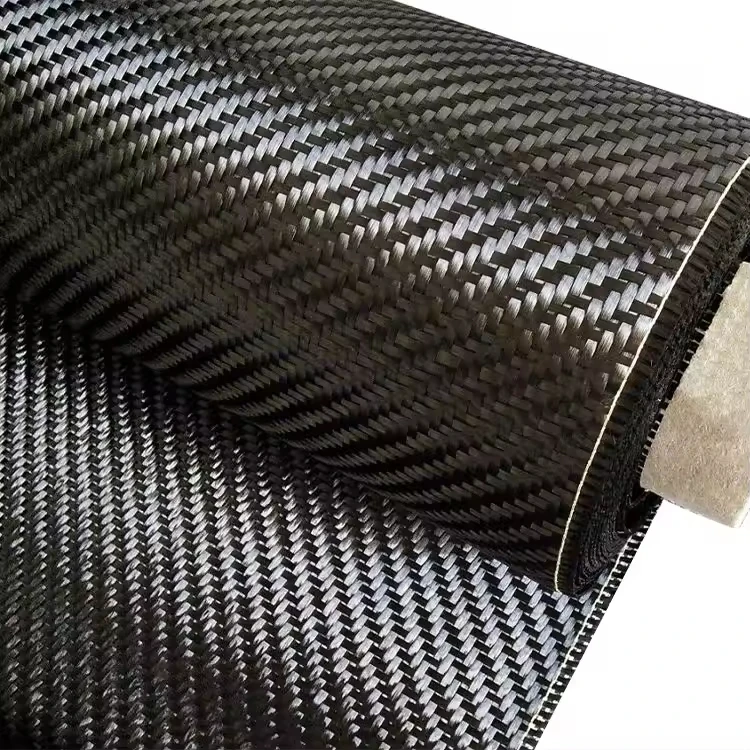

Carbon fiber is a material made from extremely thin strands of carbon atoms. Each strand is thinner than a human hair, yet when thousands of strands are aligned and bonded together, they form a structure that is exceptionally strong and very lightweight.

In real-world use, carbon fiber is almost always part of a carbon fiber composite, most commonly carbon fiber reinforced polymer (CFRP). The fibers provide strength and stiffness, while the resin holds the fibers together, transfers loads, and protects them from environmental damage.

The key point for decision-makers is this:

carbon fiber performance does not come from the material name alone, but from how the fibers are arranged, how the resin is selected, and how the product is manufactured.

How Is Carbon Fiber Made

Carbon fiber is produced through a controlled industrial process that directly affects its final performance.

At a simplified level, the process includes:

-

Spinning a precursor material (usually PAN, polyacrylonitrile) into fibers

-

Stabilizing the fibers using controlled heat in oxygen

-

Carbonizing the fibers at very high temperatures without oxygen

-

Removing non-carbon elements, leaving tightly bonded carbon atoms

-

Treating the fiber surface so it bonds effectively with resin

After this, the fibers are combined with resin and formed into products using processes such as pultrusion, filament winding, compression molding, or layered layups.

For buyers, the most important takeaway is that manufacturing discipline matters more than appearance. Inconsistent curing, poor fiber alignment, or rushed processing can significantly reduce strength and service life, even if the part looks acceptable on the surface.

Is Carbon Fiber Stronger Than Steel

Carbon fiber can be stronger than steel, depending on how strength is measured.

Steel is strong in absolute terms and performs well under compression. Carbon fiber, however, offers a much higher strength-to-weight ratio, meaning it delivers more usable strength per unit of weight.

In practice:

-

Steel gains strength by adding mass

-

Carbon fiber gains strength through fiber alignment and molecular bonding

For applications where weight reduction improves performance—such as sports equipment, UAV structures, robotic arms, and portable tools—carbon fiber often outperforms steel.

If weight is not a constraint, steel may remain the most economical option.

How Strong Is Carbon Fiber

The strength of carbon fiber varies by fiber grade, resin system, and design, but commercially accepted ranges provide a useful reference.

Typical values for structural carbon fiber composites include:

-

Tensile strength: 3,500–5,500 MPa

-

Elastic modulus: 230–600 GPa

By comparison, most structural steels fall below 600 MPa in tensile strength.

An important non-technical point:

carbon fiber is strongest along the direction of the fibers. Proper fiber orientation is critical, which is why experienced manufacturers design products around real load paths rather than relying on thickness alone.

Is Carbon Fiber Stronger Than Aluminum

Yes. Carbon fiber is significantly stronger than aluminum when compared by weight.

Common aluminum alloys such as 6061-T6 offer tensile strengths around 300 MPa. Carbon fiber composites can exceed this by an order of magnitude while remaining lighter.

Aluminum is still widely used because it is affordable and easy to machine. Carbon fiber is chosen instead when:

-

High stiffness is required

-

Fatigue resistance matters

-

Weight reduction creates measurable value

This trade-off is central to material selection in performance-driven products.

Is Carbon Fiber a Composite

Yes. Carbon fiber is a composite material.

A composite combines:

-

Carbon fibers for strength and stiffness

-

Resin for bonding, shape, and environmental protection

This structure allows manufacturers to tailor performance by adjusting fiber direction, layer thickness, and resin type. As a result, carbon fiber products are best evaluated as engineered solutions, not standardized raw materials.

Can You Paint Carbon Fiber

Carbon fiber can be painted, coated, or clear-finished without reducing structural strength when proper surface preparation is used.

Painting is commonly applied for:

-

Visual appearance and branding

-

UV protection in outdoor environments

-

Cosmetic consistency across production batches

Poor surface preparation can lead to peeling or cracking over time, so finishing quality is an important supplier evaluation point when appearance matters.

Is Carbon Fiber Stronger Than Titanium

Carbon fiber often exceeds titanium in strength-to-weight ratio, but the two materials serve different roles.

Titanium alloys are extremely strong and corrosion-resistant but are heavier and expensive to machine. Carbon fiber is typically preferred when:

-

Weight reduction is critical

-

Complex shapes are required

-

Production scalability is important

Titanium remains better suited for high-temperature or impact-heavy environments. The correct choice depends on operating conditions rather than headline strength numbers.

Is Carbon Fiber Lighter Than Aluminum

Yes. Carbon fiber is significantly lighter than aluminum.

Typical density values:

-

Carbon fiber composite: 1.55–1.65 g/cm³

-

Aluminum: approximately 2.70 g/cm³

This weight advantage improves handling, efficiency, and user experience, while also reducing shipping and operational costs over the product lifecycle.

Why Is Carbon Fiber So Strong

Carbon fiber strength comes from both chemistry and structure.

Key reasons include:

-

Strong carbon-to-carbon atomic bonds

-

Highly aligned fiber structure

-

Controlled high-temperature processing

Unlike metals, carbon fiber does not rely on bulk mass for strength. Material is placed only where it is needed, enabling high performance with minimal weight.

What Is Lighter: Fiberglass or Carbon Fiber

Carbon fiber is lighter and stiffer than fiberglass.

Fiberglass offers lower cost and moderate strength, making it suitable for cost-sensitive applications. Carbon fiber is selected when higher stiffness, lower weight, and longer-term performance justify the additional cost.

How Durable Is Carbon Fiber

Carbon fiber is highly durable when properly designed and manufactured.

Key durability advantages include:

-

No rust or corrosion

-

Excellent fatigue resistance

-

Stable long-term mechanical performance

In commercial and industrial applications, well-made carbon fiber components commonly achieve service lives of 15–30 years, depending on environment and usage conditions.

Carbon Fiber vs Common Engineering Materials (Data Comparison)

| Material | Density (g/cm³) | Tensile Strength (MPa) | Elastic Modulus (GPa) | Strength-to-Weight Performance | Typical Service Life |

|---|---|---|---|---|---|

| Carbon Fiber (CFRP) | 1.55–1.65 | 3,500–5,500 | 230–600 | Excellent | 15–30 years |

| Aluminum 6061-T6 | 2.70 | 290–310 | 69 | Moderate | 10–20 years |

| Structural Steel | 7.85 | 400–550 | 200 | Low | 20–40 years |

| Fiberglass (GFRP) | 1.9–2.1 | 900–1,500 | 35–50 | Medium | 15–25 years |

| Titanium Ti-6Al-4V | 4.43 | 900–1,100 | 110 | High | 25–40 years |

These ranges reflect commercially relevant material performance rather than laboratory extremes.

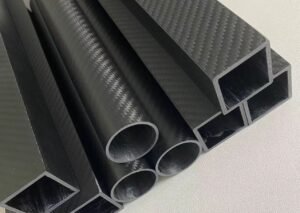

How Carbon Fiber Translates Into Real Products

Carbon fiber is rarely selected as a raw material alone. In real projects, it is chosen as a specific product form based on load direction, stiffness requirements, and manufacturing constraints.

Common product forms include carbon fiber tubes, sheets and plates, rods, and custom profiles or parts. Each form uses the same base material but delivers very different performance depending on geometry and fiber orientation.

This is where material knowledge and manufacturing experience intersect.

How to Decide If Carbon Fiber Is Right for Your Product

Before selecting carbon fiber, decision-makers should consider:

-

Does reducing weight improve performance or usability?

-

Will higher stiffness improve accuracy or durability?

-

Does longer service life justify higher upfront cost?

-

Can the supplier support consistent quality at scale?

Carbon fiber delivers value when it solves a specific performance problem, not when it is chosen for appearance alone.

How to Choose a Reliable Carbon Fiber Supplier

Material choice alone does not guarantee success. Supplier capability determines whether carbon fiber performs as expected.

A reliable supplier should:

-

Explain material options clearly and honestly

-

Provide measurable specifications and tolerances

-

Demonstrate experience with similar applications

-

Maintain consistent quality control

-

Support both prototyping and production scaling

The right supplier helps you choose the right carbon fiber solution, not simply the most expensive one.

How Carbon Fiber Is Used in Real Products

Typical Applications of Carbon Fiber Components

Typical application areas include:

Final Conclusion

Carbon fiber is one of the most effective materials available for building strong, lightweight, and durable products. It outperforms steel, aluminum, and fiberglass in many applications—but only when it is properly designed and manufactured.

For buyers and project leaders, the real question is not whether carbon fiber is “better,” but whether it is better for your specific product, budget, and long-term goals. With clear understanding and the right manufacturing partner, carbon fiber can deliver long-term value that traditional materials cannot match.