Why Customers Choose Us :

- Manufacturer-Direct Control

- Engineering Support

- Consistent Quality

- Reliable Lead Time

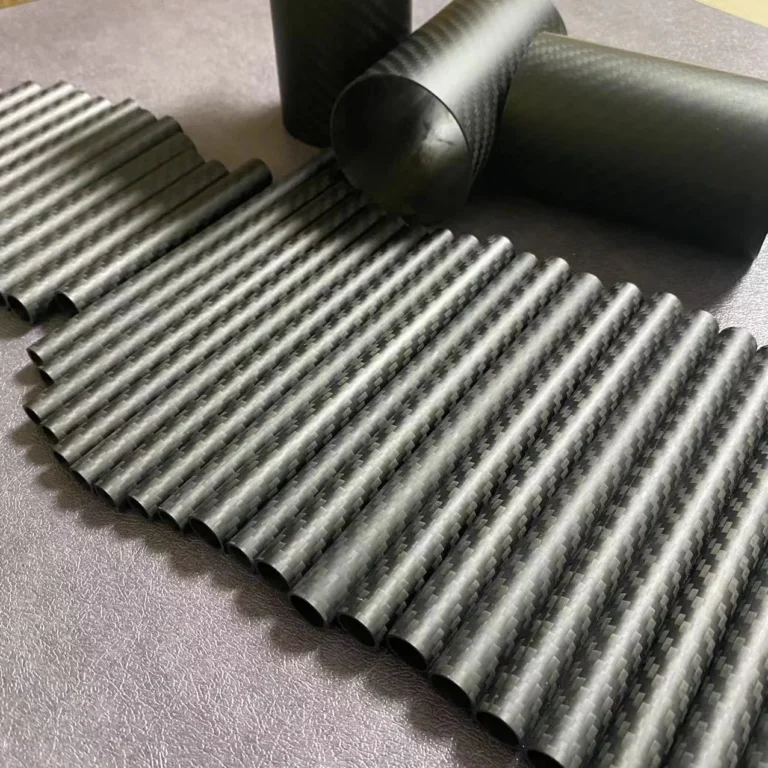

Composite tubes are high-performance structural components manufactured from fiber-reinforced composite materials.

Compared with metal tubing, composite tubing offers superior strength-to-weight ratio, corrosion resistance, and design flexibility.

In industrial and OEM applications, composite tubes are commonly supplied as carbon fiber tubes, fiberglass tubes, or carbon Kevlar tubes, depending on stiffness requirements, durability expectations, and cost targets.

Through controlled laminate design and manufacturing processes, composite tubing can be optimized for structural load, environmental exposure, and long-term dimensional stability.

Composite tubes are widely used in aerospace, robotics, industrial equipment, energy systems, and other applications where lightweight yet reliable tubular structures are required.

Composite tubes are commonly categorized by material system, as each material offers distinct mechanical performance and cost characteristics.

Composite tubes are increasingly chosen over metal tubes for lightweight, corrosion-resistant, and durable OEM applications.

| Factor | Steel Tubes | Aluminum Tubes | Composite Tubes |

|---|---|---|---|

| Density | ~7.8 g/cm³ | 2.7 g/cm³ | 1.5–2.0 g/cm³ |

| Strength-to-Weight | Low | Moderate | 2–5× aluminum |

| Corrosion Resistance | Poor (needs coating) | Good (may pit) | Excellent (no rust) |

| Typical Service Life | 5–10 yrs | 10–15 yrs | 15–25+ yrs |

| Fatigue Performance | Moderate | Moderate | High |

| Customization | Limited | Moderate | High (layup design) |

Typical engineering reference ranges based on ASTM, ASM, and ISO composite material data. Actual performance may vary by design and service conditions.

We offer flexible composite tube customization to match specific structural, dimensional, and production requirements.

Custom outer and inner diameters

Custom tube lengths and tolerances

Controlled wall thickness and laminate structures

Multi-material composite tube configurations

OEM and project-based production support

We support OEM and industrial customers with application-driven composite tube engineering and reliable manufacturing execution.

We work as a reliable composite tube manufacturing partner for OEM and industrial applications.

Composite tubes are specified based on functional requirements rather than catalog limitations.

Material systems and laminate structures are selected to meet structural and environmental demands without over-design.

We work across carbon fiber, fiberglass, and hybrid composite systems, enabling material selection to align with performance priorities, cost targets, and service conditions. This enables optimized composite tube solutions across different performance and cost targets.

Controlled processes ensure dimensional accuracy and repeatable mechanical performance across production batches, supporting stable long-term supply for OEM programs.

From early-stage material selection to production delivery, we provide responsive engineering communication and reliable execution for custom composite tube projects.

Composite tubes are used across industrial and OEM environments where lightweight, durable structural solutions are required.

• Industrial automation and robotic structures

• Energy, inspection, and access equipment

• Lightweight frames and support assemblies

• Sports and outdoor equipment

• OEM structural components

Composite tube material selection depends on structural requirements, service environment, and cost constraints.

Evaluating load conditions and durability needs helps determine the most suitable composite system for the application.

Composite tubes typically offer higher strength-to-weight and stiffness-to-weight performance than metal tubes.

Overall strength depends on structural design and application requirements rather than material type alone.

Yes. Composite tubes are commonly engineered for OEM applications with customized dimensions, laminate structures, and material systems based on project-specific requirements.