Why Customers Choose Us :

- Manufacturer-Direct Control

- Engineering Support

- Consistent Quality

- Reliable Lead Time

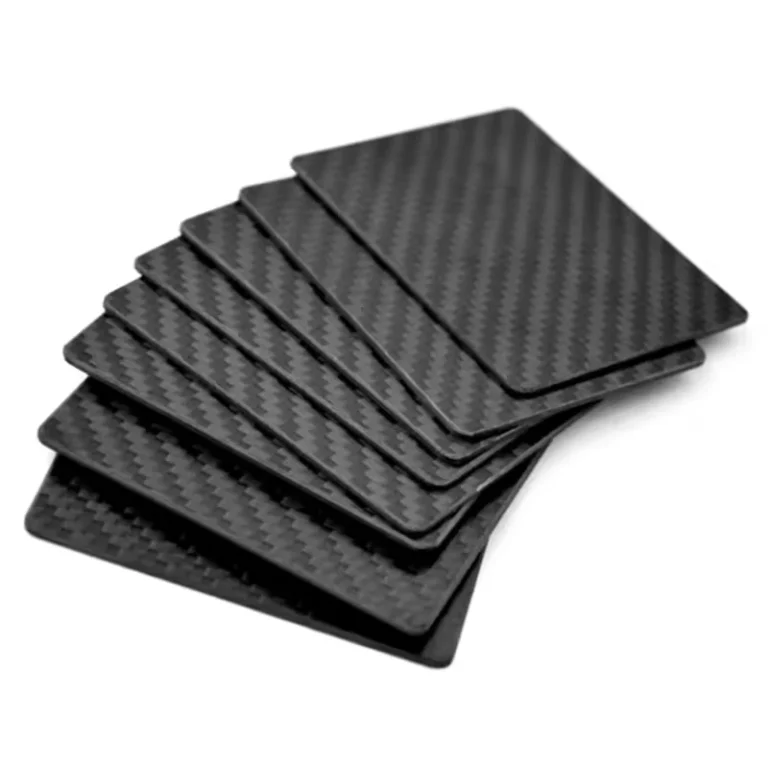

Carbon fiber panels are engineered composite panel solutions designed for applications where high structural rigidity, weight reduction, and dimensional stability are essential. Unlike basic composite raw materials, carbon fiber panels are supplied as finished or semi-finished structural components, ready for direct integration or secondary machining in OEM and industrial production.

Through controlled laminate design, fiber orientation, and panel thickness, carbon fiber panels can be precisely engineered to achieve targeted stiffness, load distribution, and impact resistance. Solid laminate panels are commonly used for rigid structural support and reinforcement, while sandwich and honeycomb panel constructions optimize bending stiffness and strength-to-weight performance for large-area or load-sensitive applications.

From a manufacturing perspective, carbon fiber panels are produced under tightly controlled processes to ensure flatness, dimensional accuracy, and repeatable mechanical properties. These panels can be CNC machined into structural panels, mounting plates, enclosure panels, interior skins, and lightweight load-bearing components without compromising material integrity. This makes carbon fiber panels well suited for custom and OEM production across architectural systems, industrial equipment, transportation platforms, and other performance-driven applications where consistency and structural reliability are critical.

For a technical overview of carbon fiber mechanical properties and design considerations, please refer to our Carbon Fiber Material Overview.

We specialize in producing high-performance carbon fiber panels tailored to meet the specific requirements of OEM applications.

Carbon fiber sandwich panels consist of carbon fiber skins bonded to lightweight core materials such as foam ,aluminum or honeycomb. This structure delivers balanced strength, stiffness, and impact resistance for engineered panel systems.

Carbon fiber honeycomb panels combine carbon fiber face sheets with a lightweight honeycomb core to achieve exceptional bending stiffness at minimal weight. They are commonly used in aerospace, transportation, and high-performance structural applications

Custom carbon fiber panels are manufactured to specific size, thickness, laminate structure, and surface requirements. They are widely supplied for OEM and engineered applications where standard panel specifications do not meet design or performance needs.

Carbon fiber floor panels are used in platforms, interiors, and load-bearing panel systems requiring high stiffness-to-weight performance. These panels resist bending and fatigue, making them suitable for repeated load and vibration environments.

Carbon fiber door panels are designed for lightweight door structures and access panels where rigidity and strength are required. Compared with traditional materials, they enable thinner panel designs while maintaining structural performance and long-term durability.

Carbon fiber wall panels are lightweight composite panels used for architectural and industrial wall-facing applications. They provide high stiffness, dimensional stability, and a consistent carbon fiber surface finish, making them suitable for both functional and decorative panel systems.

Carbon fiber panels are produced through a controlled multi-step composite manufacturing process to ensure consistent mechanical properties and surface quality.

| Step | Process Description |

| Layup | Carbon fiber fabrics or prepregs are layered according to structural load requirements |

| Lamination | Multi-directional layups are consolidated under controlled pressure |

| Curing | Panels are cured via autoclave or hot press for resin consolidation |

| Trimming | Panels are precision-trimmed to size |

| CNC Machining | Holes, slots, and complex geometries are machined |

| Inspection | Dimensional and visual quality inspection |

Carbon fiber panels are used across architectural, industrial, and structural applications where lightweight construction, high stiffness, and long-term dimensional stability are required.

Carbon fiber panels offer significant performance advantages over traditional materials such as aluminum, steel, and fiberglass panels.

| Property | Carbon Fiber Panels | Aluminum Panels |

| Weight | Extremely lightweight | Heavier |

| Stiffness | Very high | Moderate |

| Corrosion Resistance | Excellent | Requires treatment |

| Custom Layup | Yes | No |

| Structural Optimization | Directional | Isotropic |

Our carbon fiber plates are engineered and manufactured to meet the technical, quality, and consistency requirements of OEM and custom production.

Our carbon fiber panels are designed as structural components rather than decorative laminates. Fiber orientation, laminate thickness, and stacking sequence are defined to deliver predictable stiffness, load distribution, and dimensional stability.

Panels are manufactured under controlled layup and consolidation processes to maintain consistent thickness, flatness, and fiber volume fraction, ensuring repeatable mechanical performance across production batches.

We offer solid, sandwich, and honeycomb panel constructions, allowing stiffness-to-weight ratios to be tailored through laminate design and core selection instead of excessive material thickness.

Our panels are supplied in CNC-compatible formats with stable consolidation, reducing risks of delamination, fiber pull-out, and edge defects during machining and downstream processing.

In the composites industry, the terms carbon fiber panels and carbon fiber sheets are often used interchangeably in marketing contexts.

However, in engineering specifications, procurement documents, and industry standards, the two terms typically reflect different levels of definition, control, and intended use.

This distinction is not semantic—it directly affects structural performance, machining reliability, and batch consistency in OEM applications.

In most composite standards and technical documentation (including ASTM and ISO composite material classifications),

the term “sheet” is commonly used to describe a flat material form—a laminated composite supplied primarily by thickness, size, and resin system.

By contrast, “panel” is widely used in engineering and manufacturing contexts to describe a structural flat component, where additional performance-related parameters are controlled, such as:

Thickness tolerance and panel flatness

Fiber volume consistency

Consolidation quality and void control

Suitability for machining and assembly

As a result, panels are typically specified when the composite part functions as a load-carrying or stiffness-critical element, rather than a generic laminate.

This distinction aligns with how composite panels are defined and inspected in aerospace, industrial equipment, and transportation supply chains.

From a manufacturing standpoint, carbon fiber panels are produced with panel-level quality objectives, not only laminate-level targets.

While carbon fiber sheets may meet basic thickness or material specifications, panels are commonly manufactured with additional controls applied to:

Panel flatness and warpage

Through-thickness consistency

Resin distribution and consolidation uniformity

Edge integrity after cutting or machining

These parameters are critical for downstream CNC processing and mechanical assembly, which is why OEM drawings and RFQs often specify “panel” rather than “sheet.”

Another practical distinction is structural scope.

In industry usage, the term carbon fiber panels routinely includes:

Solid laminate panels

Sandwich panels

Honeycomb core panels

These constructions are defined and evaluated at the panel level, since their mechanical performance depends on skin–core interaction, bonding integrity, and bending stiffness—not on laminate thickness alone.

Such structures are rarely classified as “sheets” in engineering documentation, even though they may appear flat in form.

| Aspect | Carbon Fiber Sheets | Carbon Fiber Panels |

|---|---|---|

| Common definition basis | Material form | Engineered structural component |

| Typical specification | Thickness, size, resin | Flatness, tolerance, structural consistency |

| Structural scope | Mostly solid laminates | Solid, sandwich, honeycomb |

| CNC machining expectation | Application-dependent | Explicitly considered |

| Typical use cases | General laminates, covers | OEM structural and functional parts |

Carbon fiber sheets are often sufficient for applications where:

Structural loads are low

Dimensional tolerance is non-critical

Appearance or basic material availability is the priority

Carbon fiber panels are typically specified when projects require:

Verifiable and repeatable structural performance

Stable CNC machining behavior

Controlled flatness and assembly fit

Consistent quality across production batches

These requirements are common in UAV structures, robotics platforms, industrial machinery, and lightweight transportation systems, where panels are treated as functional components rather than raw material.

In industry practice, the difference between carbon fiber sheets and carbon fiber panels is driven by how the material is specified, controlled, and used, not by terminology preference.

When a project requires panel-level structural reliability and manufacturing consistency, carbon fiber panels represent a more accurate and lower-risk sourcing category than generic carbon fiber sheets.

Carbon fiber panels are used in applications requiring lightweight structural support and high stiffness.

They are widely applied in automotive components, aerospace interiors, industrial equipment housings, robotics structures, and performance-oriented products.

A carbon fiber sandwich panel is a lightweight panel consisting of carbon fiber skins bonded to a core material.

Yes, carbon fiber panels are suitable for CNC machining when manufactured with controlled laminate structures.

Carbon fiber panels are superior to steel panels in applications where weight reduction and stiffness efficiency are critical.

Carbon fiber panels are flat composite structures made from carbon fiber layers bonded with resin.