Why Customers Choose Us :

- Manufacturer-Direct Control

- Engineering Support

- Consistent Quality

- Reliable Lead Time

Carbon fiber sports equipment refers to athletic products that use carbon fiber composites as structural materials in performance-driven designs.

From professional competition gear to consumer-level sports products, carbon fiber is widely applied in shafts, frames, boards, and other load-bearing components.

In sports equipment manufacturing, carbon fiber is selected not for decoration, but for its ability to deliver consistent mechanical performance, weight reduction, and structural efficiency across different product types.

As a result, it has become a standard material solution for a wide range of modern sports equipment applications.

The selection of carbon fiber for this application is based on its mechanical performance and design constraints, as explained in our Carbon Fiber Material Reference.

The following categories outline common types of sports equipment that utilize carbon fiber in shafts, frames, boards, and other load-bearing components.

Carbon fiber is most widely applied in shaft-based sports equipment where weight, straightness, and flex characteristics directly influence performance.

Typical products include golf shafts, ice hockey sticks, field hockey sticks, floorball sticks, lacrosse shafts, polo mallet shafts, baseball bats, softball bats, cricket bat handles and shafts and cue shafts.

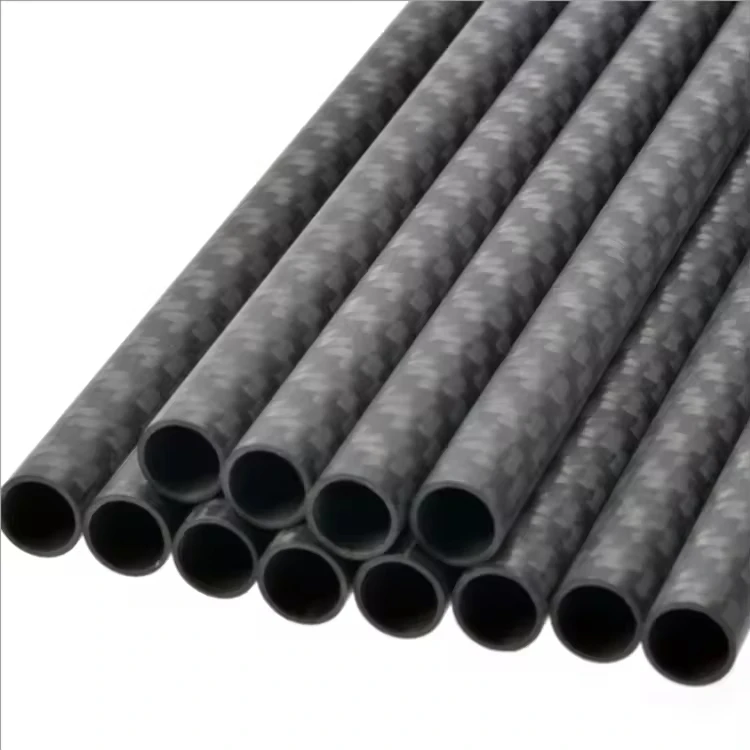

These products primarily rely on carbon fiber tubes and rods as their core structural elements.

In precision sports, carbon fiber is used to ensure dimensional stability and repeatable performance.

Common applications include carbon fiber arrow shafts, crossbow bolts, archery stabilizer rods, as well as sight bars and extender rods used in competitive archery systems.

Many modern racket sports utilize carbon fiber to balance stiffness, vibration damping, and swing consistency.

Typical products include tennis rackets, badminton rackets, squash rackets, padel rackets, beach tennis rackets, and platform tennis paddles, where carbon fiber is integrated into frames, shafts, or reinforced structures.

Carbon fiber is also widely used in paddle-type sports products to reduce weight while maintaining rigidity.

Examples include pickleball paddles, SUP paddles, kayak paddles, and canoe paddles, where carbon fiber shafts or laminated structures improve handling and durability.

Cycling is one of the most advanced application areas for carbon fiber composites.

Carbon fiber is commonly used in bicycle frames, bicycle forks, handlebars, stems, seatposts, wheel rims, spokes, and hub shells, where high stiffness-to-weight ratio and fatigue resistance are critical.

In water-based sports, carbon fiber provides corrosion resistance and structural efficiency.

Typical products include windsurf masts, windsurf booms, carbon-reinforced surfboards, hydrofoil masts, hydrofoil wings, and diving fins, all designed to perform under dynamic loads and harsh environments.

Carbon fiber is widely used in fishing and marine sports equipment due to its lightweight strength and resistance to moisture.

Common applications include fishing rods, boat fishing rods, landing net handles, and outrigger poles, where tubular carbon fiber structures are essential.

In winter and Nordic sports, carbon fiber helps reduce overall equipment weight while maintaining structural stability in cold conditions.

Applications include ski poles, Nordic walking poles, walking poles, roller ski poles, as well as carbon-reinforced skis and carbon-reinforced snowboards.

Carbon fiber laminates and reinforced structures are increasingly used in board and action sports to tune flex and impact resistance.

Typical products include skateboard decks, longboard decks, scooter decks, scooter handlebars, and BMX reinforced parts used in freestyle and competitive riding.

Carbon fiber is also applied in professional training and performance equipment where portability and durability are required.

Examples include training poles, agility poles, and slalom poles used in sports training systems and competitive setups.

In track and field disciplines, carbon fiber is selected for its stiffness and energy-storage characteristics.

Typical products include pole vault poles, javelin shafts, and relay batons, where controlled flex and strength are essential.

Beyond athlete-handled equipment, carbon fiber is used in sports event and competition infrastructure.

Applications include beach flag poles, telescopic flag poles, and course marker poles, where lightweight transport and outdoor durability are important.

Different sports applications require different composite forms.

Below is how carbon fiber tubes, sheets, rods, and parts are typically used in sports equipment.

Bicycle frames and sub-frames

Racket shafts and structural arms

Fitness and training equipment frames

Why Tubes

Excellent stiffness-to-weight ratio

Ideal for load-bearing and frame structures

Flexible diameter and wall thickness customization

→ Learn more about Carbon Fiber Tubes

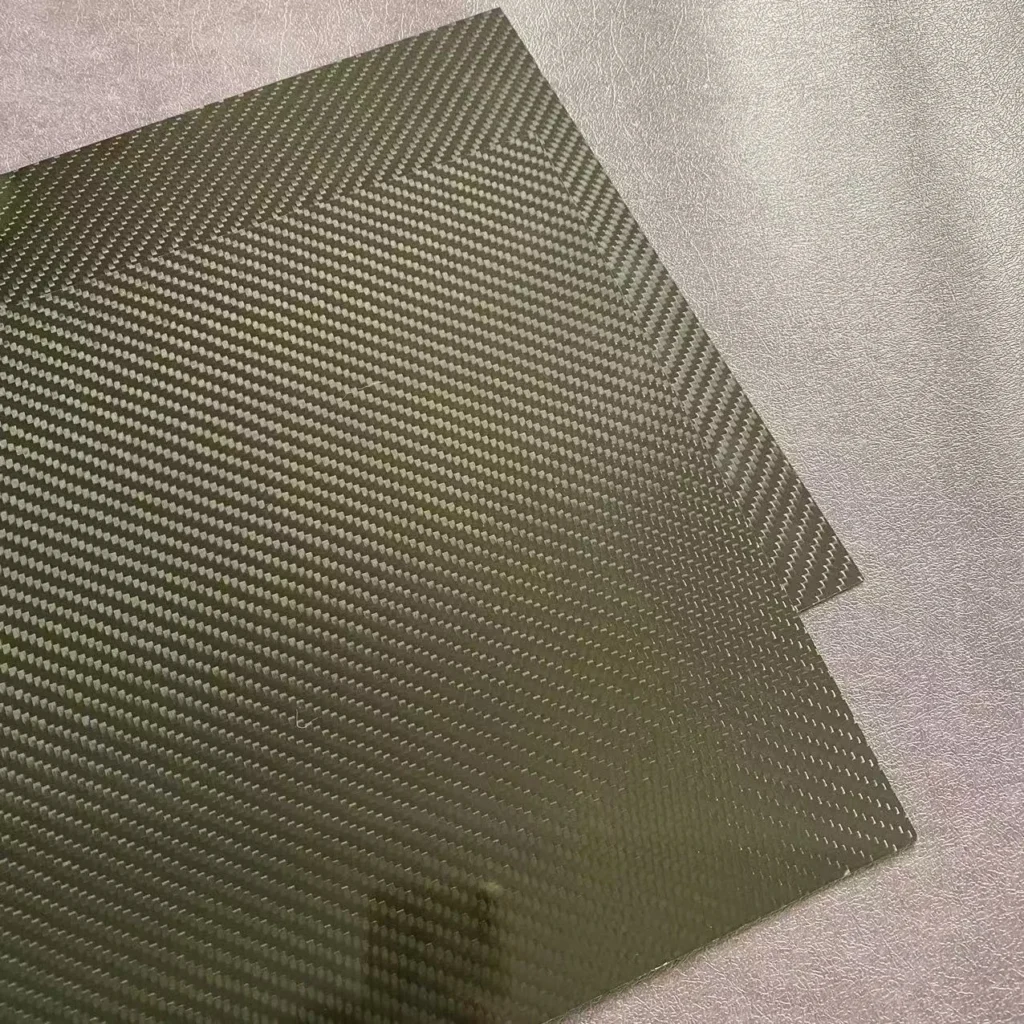

Board-based sports equipment and decks

Structural panels for cycling and training systems

Reinforcement plates and flat composite components

CNC-machined sports equipment parts

Why Carbon Fiber Sheets & Plates

High in-plane stiffness and dimensional stability

Suitable for flat and load-distribution structures

Compatible with machining and secondary processing

→ Learn more about Carbon Fiber Seets & Plates

Fishing rods

Training poles and lightweight supports

Flexible structural elements

Why Rods

Controlled flex and elasticity

Lightweight and fatigue-resistant

Consistent mechanical performance

→ Learn more about Carbon Fiber Rods

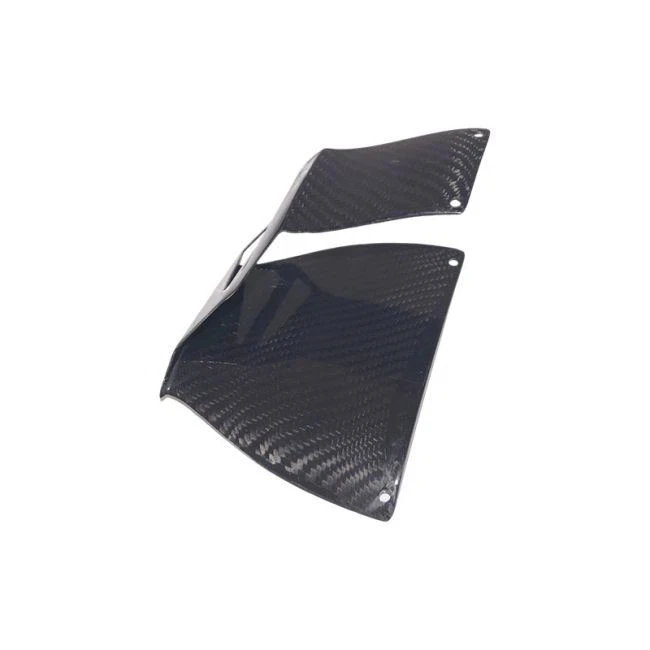

Custom brackets and connectors

Structural reinforcement parts

OEM sports equipment components

Why Parts & Profiles

Complex shapes and functional integration

Design freedom for OEM products

Suitable for small-batch and mass production

→ Learn more about Custom Carbon Fiber Parts

| Sports Equipment Application | Recommended Product Form | Key Benefit |

|---|---|---|

| Bicycle frames | Carbon Fiber Tubes | Lightweight & high stiffness |

| Racket shafts & frames | Tubes / Sheets | Speed & vibration control |

| Fishing rods | Carbon Fiber Rods | Controlled flex |

| Protective panels | Sheets / Panels | Impact resistance |

| Custom sports structures | Parts & Profiles | Design flexibility |

Carbon fiber is widely adopted in sports equipment manufacturing due to:

These properties allow sports equipment designers to optimize performance beyond traditional metal materials.

Case 1: Composite Tubes for Racket Shafts & Sports Structural Arms

Application Background

A sports equipment manufacturer required lightweight composite tubes for racket shafts and structural arms used in competitive sports equipment.

The design emphasized stiffness control, dimensional consistency, and reliable performance under repeated swinging and impact loads.

Our Composite Tube Solution

We supplied composite tubes with controlled diameter, wall thickness, and fiber layup to meet shaft-specific stiffness and strength requirements.

The tubes were produced with consistent straightness and surface quality to support downstream assembly and finishing.

Results & Benefits

Case 2: Composite Rods for Training Poles & Lightweight Sports Supports

Application Background

A training equipment supplier required lightweight rods for agility poles and portable sports training systems.

Key requirements included controlled flex, fatigue resistance, and durability under frequent setup and repetitive use.

Our Composite Rod Solution

Composite rods were supplied with tailored fiber orientation and diameter specifications to achieve the desired balance between stiffness and flexibility.

Production focused on uniform mechanical properties and reliable performance across multiple batches.

Results & Benefits

Case 3: Carbon Fiber Sheets & Custom Parts for Paddle and Board-Based Sports Equipment

Application Background

A sports equipment OEM required flat composite laminates and custom structural parts for paddle and board-based sports products.

The application demanded high stiffness, dimensional stability, and compatibility with CNC machining and secondary processing.

Our Composite Solution

We supplied carbon fiber sheets and plates for machining, along with custom carbon fiber parts and profiles for localized reinforcement.

Layup configurations were optimized to support load distribution and structural integrity in high-stress areas.

Results & Benefits

Carbon fiber is used in sports equipment because it provides high structural strength with low weight.

This allows designers to control stiffness, reduce fatigue during use, and maintain consistent performance across repeated loading cycles.

Carbon fiber improves sports equipment performance by optimizing stiffness, flex response, and weight distribution.

These characteristics enhance handling, energy transfer, and stability in shaft-based, frame-based, and board-based products.

Carbon fiber itself does not dry out, but the resin matrix and surface finish require protection.

Proper coatings, UV-resistant finishes, and avoiding prolonged exposure to extreme heat help maintain long-term surface integrity and performance.

Carbon fiber sports equipment solutions include tubes, rods, sheets, plates, and custom composite parts tailored to specific applications.

Design parameters such as geometry, layup structure, and stiffness can be adjusted to meet sport-specific performance requirements.

Carbon fiber is commonly used in shaft-based, frame-based, and board-based sports equipment.

Typical examples include sports shafts, rackets, paddles, cycling components, boards, and structural training or event equipment.

Yes, carbon fiber components are widely used in professional and competition-level sports equipment.

Their consistent mechanical performance and lightweight structure make them suitable for high-performance applications.

Yes, carbon fiber is well suited for outdoor and water sports equipment.

It offers corrosion resistance and stable mechanical performance in humid, marine, and outdoor environments.

We provide a complete portfolio of composite products for sports equipment applications: