Why Customers Choose Us :

- Manufacturer-Direct Control

- Engineering Support

- Consistent Quality

- Reliable Lead Time

Carbon fiber is widely used in protective and safety applications that require high strength, impact resistance, and lightweight structural performance.

In industrial, utility, and public safety environments, carbon fiber composites provide durable, corrosion-resistant protection for equipment and structural systems.

Material-level properties that make carbon fiber suitable for this application are discussed in our Carbon Fiber Material Guide.

We manufacture carbon fiber protective and safety components as structural composite parts for OEM and custom applications.

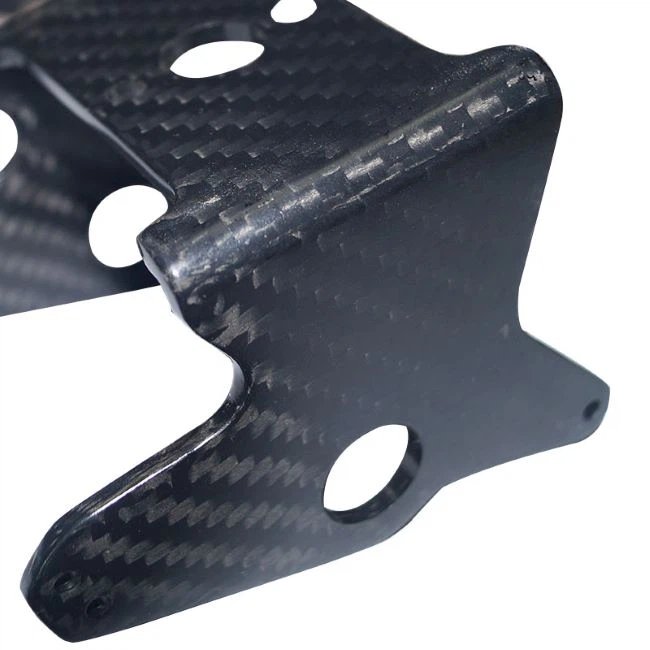

Carbon fiber guards are manufactured as lightweight protective composite components designed to resist impact, abrasion, and repeated mechanical stress.

This category covers a wide range of guard structures used in professional and consumer-facing protective products, including carbon fiber shin guards, carbon fiber soccer shin guards, carbon fiber leg guards, and carbon fiber fork guards.

Carbon fiber covers are produced as protective composite structures used to shield equipment and components from impact, debris, and environmental exposure.

Common applications include carbon fiber protective covers, carbon fiber equipment covers, composite housings, and custom cover panels, as well as structural components used in finished products such as carbon fiber wheel covers, carbon fiber seat covers, and carbon fiber mirror covers.

Carbon fiber handles are structural grip and support components designed for strength, control, and reduced weight in safety and protective equipment.

This category includes carbon fiber tool handles, ergonomic safety grips, reinforced composite handles, and carbon fiber face shield support handles used in professional tools and protective systems.

Carbon fiber helmet components are manufactured as high-strength protective shells designed to provide impact resistance and structural integrity.

Our manufacturing capabilities support a wide range of helmet structures, including carbon fiber helmets, carbon fiber safety helmets, carbon fiber construction helmets, carbon fiber crash helmets, and carbon fiber motorcycle helmet shells, supplied as OEM composite components.

Carbon fiber protective and safety components are manufactured using different composite product forms to meet specific structural, impact, and integration requirements.

Carbon fiber tubes are widely used in protective and safety applications where structural stiffness, load-bearing capacity, and lightweight performance are required.

They are commonly applied in safety frames, protective supports, safety poles, and structural elements for equipment and enclosures.

Carbon fiber tubes allow protective systems to achieve high rigidity while reducing overall weight, improving handling and installation efficiency.

→ Learn more about Carbon Fiber Tubes

Carbon fiber sheets and panels are used to create flat or contoured protective surfaces in safety-critical systems.

These forms are commonly applied in impact protection panels, equipment covers, safety enclosures, and reinforced protective shells.

By adjusting laminate thickness and fiber orientation, sheets and panels can be optimized for impact resistance, durability, and surface stability.

→ Learn more about Carbon Fiber Seets & Plates

Custom carbon fiber parts and profiles are developed for application-specific protective and safety requirements that cannot be met by standard product forms alone.

These components include custom-shaped guards, protective housings, structural frames, and integrated safety elements designed for OEM systems.

Through tailored laminate design and controlled fabrication, custom parts support complex protective structures while maintaining lightweight performance.

→ Learn more about Carbon Fiber Parts & Profiles

Carbon fiber rods are used in protective and safety applications where axial stiffness, dimensional stability, and controlled strength are required in compact structural elements.

They are commonly applied in safety tool components, reinforced supports, internal structural members, and protective assemblies that require precise load transfer.

Compared with hollow tubes, carbon fiber rods provide solid cross-section strength and consistent performance, making them suitable for safety systems where rigidity and reliability are critical.

→ Learn more about Carbon Fiber Rods

Carbon fiber product forms used in protective and safety systems are selected based on structural performance requirements, impact behavior, and operational conditions.

| Safety / Design Requirement | Recommended Carbon Fiber Form | Engineering Rationale |

| Impact protection & surface shielding | Carbon Fiber Sheets / Panels / Plates | Laminated panels distribute impact loads over a larger area and can be tuned through fiber orientation and thickness for controlled energy absorption. |

| Load-bearing structural support | Carbon Fiber Tubes | Hollow tubular structures provide high bending stiffness and strength-to-weight efficiency for frames and protective supports. |

| Axial strength & compact reinforcement | Carbon Fiber Rods | Solid cross-section rods deliver consistent axial stiffness and dimensional stability in confined or high-load safety components. |

| Application-specific protective structures | Custom Carbon Fiber Parts & Profiles | Custom layups and geometries allow protective components to meet precise safety, integration, and durability requirements. |

In protective and safety systems, material selection directly affects structural reliability, handling safety, and long-term performance.

Carbon fiber provides a high strength-to-weight ratio, allowing protective components to meet structural and impact requirements without adding unnecessary mass.

This is especially important for wearable protection, portable safety equipment, and operator-handled tools where excessive weight can increase fatigue and risk.

Through laminate design and fiber orientation control, carbon fiber components can be engineered to manage impact loads and maintain structural integrity.

This enables protective systems to achieve consistent performance under repeated or localized impact conditions.

Carbon fiber composites offer strong resistance to corrosion, moisture, and chemical exposure.

In industrial, outdoor, and public safety environments, this durability supports longer service life and more stable performance compared with conventional metal structures.

Carbon fiber allows protective components to be tailored in shape, thickness, and reinforcement layout to meet application-specific safety requirements.

This design flexibility enables integration into complex protective systems without compromising structural performance.

Properly manufactured carbon fiber components maintain dimensional stability and mechanical consistency over time.

This reliability is essential for safety applications where performance degradation can affect system integrity and user protection.

In protective and safety applications, carbon fiber components are engineered as structural elements rather than decorative parts.

We specialize in OEM composite manufacturing for impact-resistant and durable safety components.

We manufacture carbon fiber guards, covers, handles, helmet shells, and structural components used in safety-oriented systems for industrial, professional, and public environments.

Each component is developed as part of a larger protective system, with design decisions driven by load paths, impact zones, and integration requirements rather than appearance alone.

Protective components are engineered based on real operating conditions, including impact exposure, repeated mechanical loading, and environmental factors.

Laminate structure, thickness distribution, and reinforcement layout are defined to support predictable structural behavior and consistent performance in safety-critical use.

Safety-related composite parts demand a high level of manufacturing control.

Our production emphasizes controlled layup procedures, dimensional verification, and in-process inspection to maintain consistency across batches and support repeatable OEM programs.

We support both custom development projects and ongoing production programs for protective and safety equipment.

By aligning engineering intent, manufacturing processes, and quality control, we help customers deliver protective systems that remain reliable throughout their service life.

Application Requirement

A customer developing a protective and safety system required lightweight yet structurally reliable composite components for use in a safety-critical environment.

The components needed to provide consistent impact protection and structural stability while remaining easy to handle and integrate into existing assemblies.

Key requirements included:

Carbon Fiber Solution

Based on the application requirements, carbon fiber was selected as the core material for the protective system.

We supplied a combination of carbon fiber guards, protective covers, and structural support components, manufactured as OEM composite parts for system-level integration.

Design considerations included:

All components were manufactured under controlled processes to ensure dimensional consistency and repeatable performance across production batches.

Engineering Outcome

The resulting carbon fiber protective components met the customer’s structural and integration requirements while significantly improving overall system handling.

By replacing heavier conventional materials with carbon fiber composites, the protective system achieved a more efficient balance between structural reliability, durability, and weight control, supporting long-term use in safety-oriented applications.

This project demonstrates how carbon fiber composite components can be effectively applied as functional structural elements in protective and safety systems rather than decorative parts.

Carbon fiber guards are used for impact protection and structural shielding in safety and protective systems.

They are commonly manufactured as carbon fiber shin guards, carbon fiber soccer shin guards, carbon fiber leg guards, and carbon fiber fork guards, supplied as structural composite components for OEM integration.

Yes. Carbon fiber shin guards are designed as rigid protective shells that provide high stiffness and impact resistance while remaining lightweight.

Their structural performance depends on laminate design, thickness, and reinforcement layout rather than appearance.

Carbon fiber covers are used to protect equipment and components from impact, debris, and environmental exposure.

They may be supplied as carbon fiber protective covers, carbon fiber equipment covers, or composite housings, and can also be used as structural components in finished products such as carbon fiber wheel covers or carbon fiber seat covers.

Yes. Carbon fiber handles are widely used in safety and protective equipment where strength, control, and reduced weight are required.

Typical applications include carbon fiber tool handles, ergonomic safety grips, and carbon fiber face shield support handles manufactured as OEM composite components.

A carbon fiber helmet is typically constructed using layered carbon fiber fabrics and resin systems to form a rigid protective shell.

Carbon fiber helmet structures, including carbon fiber safety helmets, carbon fiber construction helmets, carbon fiber crash helmets, and carbon fiber motorcycle helmet shells, are supplied as composite shells for further system integration.

Carbon fiber helmets can provide excellent structural stiffness and impact performance when properly engineered.

Safety performance depends on shell design, laminate structure, and system-level integration rather than material choice alone.

Yes. Carbon fiber protective products such as guards, covers, handles, and helmet shells are commonly manufactured as custom OEM components.

Dimensions, laminate structure, reinforcement zones, and surface finish can be tailored to meet specific application requirements.

Carbon fiber protective and safety products are typically manufactured by OEM composite manufacturers specializing in structural carbon fiber components.

These manufacturers supply parts for professional, industrial, and consumer-facing safety products rather than finished retail goods.

The following composite products are commonly used as structural components in protective and safety systems and are available for OEM integration.