Why Customers Choose Us :

- Manufacturer-Direct Control

- Engineering Support

- Consistent Quality

- Reliable Lead Time

We focus on manufacturing custom carbon fiber and composite components for OEM customers worldwide.

With in-house production, process control, and export experience, we support projects requiring structural reliability, consistency, and long-term supply stability.

We manufacture standard composite product forms and OEM-specific components, designed for structural performance, machining compatibility, and long-term service reliability.

Carbon fiber tubes, fiberglass tubes, and carbon kevlar tubes for lightweight structural and load-bearing use.

Diameter, wall thickness, fiber orientation, and resin systems can be customized as required.

Carbon fiber sheets, plates, and panels supplied for CNC machining and flat structural reinforcement.

Layup structure, thickness range, and surface finish are defined according to processing methods and end-use requirements.

Carbon fiber rods and fiberglass rods produced for applications requiring consistent stiffness and dimensional stability.

Suitable for shafts, supports, reinforcement elements, and industrial or sporting components.

Carbon fiber strips, forged carbon fiber parts, channels, and brackets designed as functional structural components.

Commonly used for reinforcement, mounting, load transfer, and lightweight assembly integration.

We manufacture OEM carbon fiber and composite components tailored to specific application requirements across multiple industries.

Carbon arrow shafts, pool cues, hockey shafts, lacrosse shafts and sporting CFRP components

OEM carbon fiber and composite products manufactured for stiffness, weight reduction, and performance-driven sports equipment applications.

Cleaning poles, inspection poles, field tools and telescoping composite components

Lightweight and durable carbon fiber products optimized for portability, reach, and operational reliability in outdoor tools.

Drone frames, arms, landing gear and lightweight structural components

High-strength carbon fiber structures engineered for optimized strength-to-weight performance in UAV and drone applications.

Robot arms, booms, structural links and custom CFRP components

Precision-manufactured composite parts designed for rigidity, dimensional stability, and dynamic performance in robotic systems.

Structural reinforcements, interior trim parts and custom CFRP components

Carbon fiber solutions focused on weight reduction, functional integration, and durability for automotive and mobility applications.

Cleaning poles, inspection poles, field tools and telescoping composite components

Lightweight and durable carbon fiber products optimized for portability, reach, and operational reliability in outdoor tools.

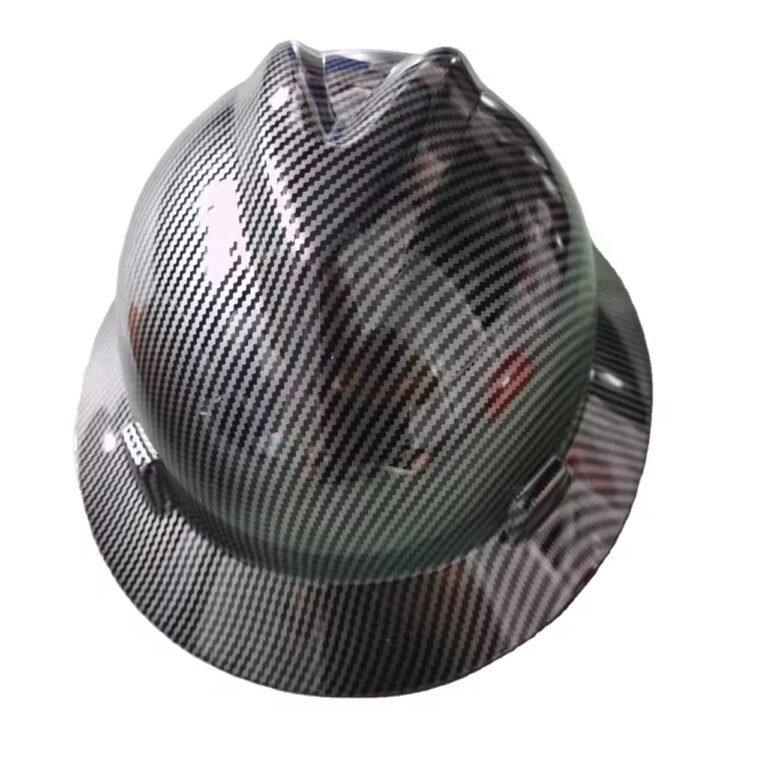

Protective inserts, helms,reinforcement panels and impact-resistant composite components

Carbon fiber and composite parts engineered for protection, structural integrity, and safety-critical applications.

Examples of how our composite products are integrated into real OEM applications.

Custom carbon fiber pool cue shafts developed to achieve high straightness, controlled stiffness, and consistent feel.

The composite structure improves dimensional stability and reduces sensitivity to humidity and temperature changes compared to traditional materials.

Custom telescoping carbon fiber tubes designed for lightweight extension, controlled stiffness, and smooth sliding performance.

Tube straightness, surface finish, and dimensional tolerances are optimized to ensure reliable extension, locking, and long-term durability.

Lightweight carbon fiber components developed for UAV frames and structural assemblies, focusing on strength-to-weight efficiency and structural stability.

Composite design improves stiffness and vibration control while supporting consistent performance across repeatable production batches.

OEM-focused carbon fiber and composite solutions manufactured strictly to customer drawings and specifications.

Custom carbon fiber tubes, sheets, plates, and composite components supported from prototyping to stable volume production, with controlled processes and in-house quality inspection.

OEM-focused carbon fiber and composite manufacturing for customers requiring reliability, control, and long-term supply stability.

Across sports equipment, industrial & utility tools, UAV & drone, and protective composite applications.

Serving OEM customers across sports equipment, industrial tools, UAV & drone, and utility applications with repeat production programs.

Across repeat OEM programs with controlled processes and consistent quality standards.

Experience working with international OEM requirements, drawings, documentation, and quality expectations.

Supporting OEM projects from development to long-term production supply.

Applied throughout OEM production to ensure consistent and repeatable quality.

A structured manufacturing workflow ensuring consistent quality, accuracy, and repeatable OEM production.

Project requirements are reviewed with manufacturability and structural performance in mind.

Manufacturing methods and layup structures are defined and validated through prototypes when required.

Dimensional checks and process inspections ensure consistency throughout production.

Approved processes are applied to repeatable batch production with controlled quality output.

Why Customers Choose to Stay with Us

Top 10 Carbon Fiber Tube Manufacturers & Suppliers in the World 2026 Carbon fiber tubes...